15 Manufacturing workforce communication challenges holding back today’s factories

Imagine ordering a custom-built motorcycle online. The design looks perfect on screen, the specs are clear, and the confirmation email says everything is locked in. Weeks later, it arrives with the right engine, the wrong handlebars, and a paint shade that feels almost right. No single step failed. The issue was small interpretation gaps between design, supplier, assembler, and delivery.

That is exactly how manufacturing workforce communication challenges manifest within factories today. Messages leave leadership with clarity and urgency, yet arrive on the floor slightly altered. A key detail dropped during handover, a shift change missed, or a language nuance lost along the way.

Over time, these small disconnects compound. Morale dips, trust erodes, and execution slows. Fixing communication is not about speaking louder or repeating instructions. It is about designing messages that survive the journey intact, regardless of the number of shifts, tools, or people they pass through.

- Manufacturing workforce communication challenges arise when messages break across shifts, roles, languages, and channels.

- Fragmented systems, weak handovers, and poor feedback loops quietly hurt safety, quality, and schedules.

- Small communication gaps compound into rework, delays, low trust, and rising attrition.

- Morale improves when communication is timely, two-way, and consistent on the factory floor.

- Clear protocols, simple tools, and disciplined manager communication reduce risk and restore alignment.

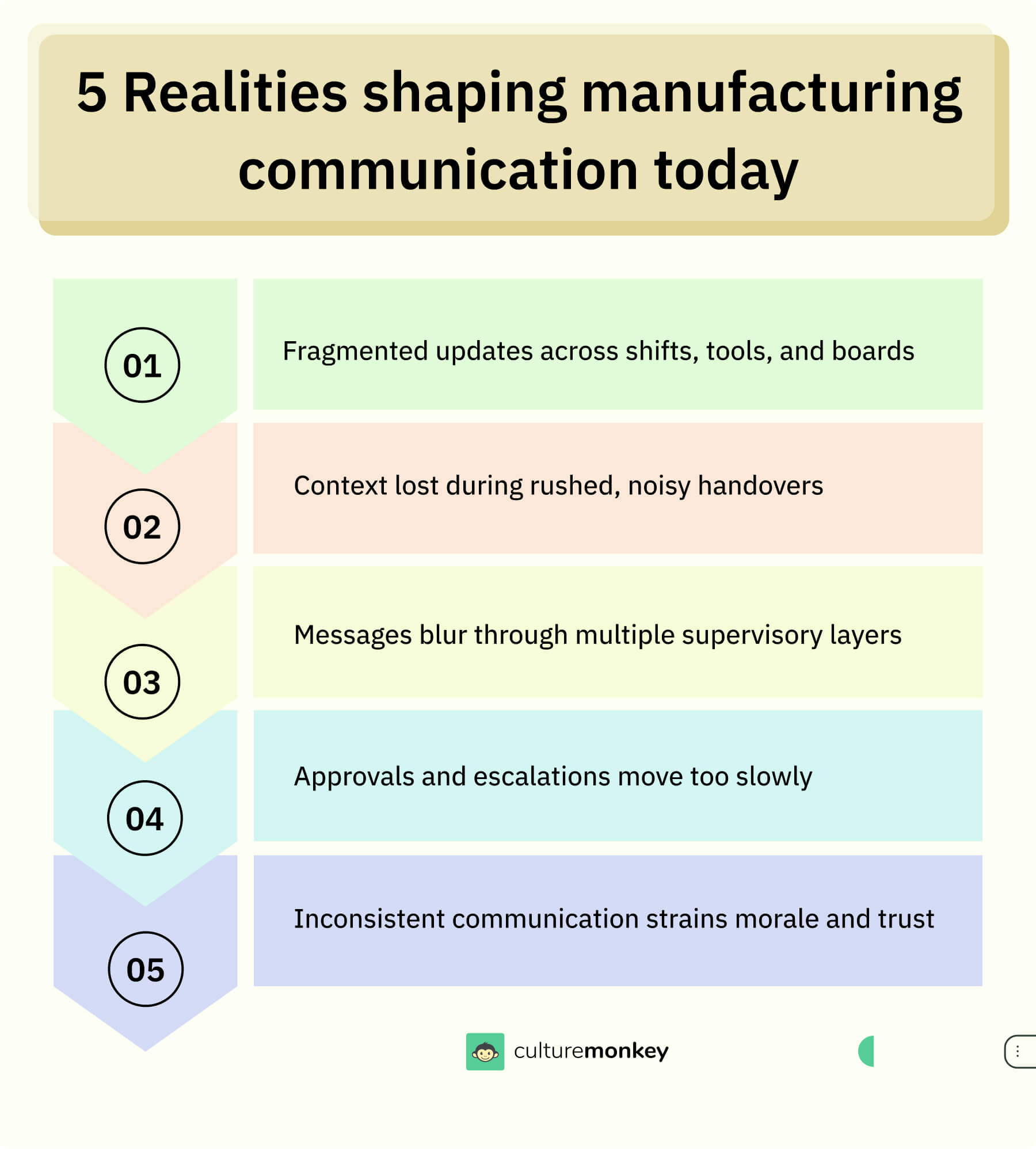

What manufacturing communication challenges look like today?

Manufacturing communication challenges today surface when messages lose clarity as they travel across shifts, roles, and languages. Production floor communication depends on fragmented manufacturing communication systems, so shift handovers leak context and leaders assume understanding that never fully lands. Even with good intent, communication success drops before anyone notices the source.

Language barrier issues turn into silent errors on the floor. Instructions get shortened, translated on the fly, or skipped in noisy environments, slowing execution and increasing rework. When manufacturing communication tools are spread across paper notices, messaging apps, and emails, teams chase updates instead of acting on them.

The impact compounds when approvals move slowly and feedback flows one way. Dashboards highlight output, not confusion, and without top survey tools for manufacturing companies, leaders miss early warning signs. Strong manufacturing communication solutions, aligned with a clear manufacturing workforce engagement strategy and practical ways to boost employee morale, including fun ways to boost morale at work, help rebuild clarity, trust, and momentum across shifts.

The 15 most common communication challenges manufacturers struggle with

Manufacturing workforce communication challenges 2026 are like a factory conveyor with one loose roller: everything still moves, but it wobbles, scrapes, and slows the whole line.

Use these manufacturing workforce communication challenges examples to spot where messages bend, where updates vanish, and where teams lose trust across shifts before defects appear.

1. Inconsistent quality control communication

When quality instructions change by shift or supervisor, teams chase defects instead of preventing them. Grammarly estimates that miscommunication costs U.S. businesses $1.2 trillion annually (Source: Grammarly).

On the floor, there are repeated inspections, unclear defect tags, and rework loops. Lock one version of specs, add photo examples, and confirm updates every shift.

2. Overreliance on supervisors as communication relays

When systems fail, supervisors become the default messengers. This overloads managers with repetitive explanations and leaves less time for coaching or problem-solving.

Clear systems that deliver consistent messages directly to teams reduce dependency on verbal relays and allow supervisors to focus on leadership instead of translation.

3. Executive communication that does not reach frontline teams clearly

Leadership can be crystal clear, yet the message never lands where work happens. Deloitte found that only 23% of frontline workers feel they have the technology they need to be productive (Source: Deloitte).

If comms ride on email or meetings, they miss. Convert strategy into shift-ready briefs, visuals, and role-specific actions, then validate understanding.

4. Supplier and vendor communication breakdowns

Manufacturers rely on external partners for materials, specs, and timelines. When updates arrive late or incomplete, internal teams absorb the impact through rework and delays.

Clear intake formats, version control, and shared timelines help prevent misunderstandings and reduce blame cycles between suppliers, planners, and production teams.

5. Lack of feedback loops between managers and employees

When the floor lacks a fast, safe way to raise concerns, small issues repeat until they cause downtime. In the manufacturing industry, Gallup shows that only one in three employees feels recognised, and those who do not feel recognised are twice as likely to consider quitting (Source: Gallup).

Weak feedback undermines effective communication, especially for manufacturing businesses operating across shifts in the manufacturing sector.

6. Information overload during peak operations

Too many messages arriving at once cause teams to tune out entirely. During peak periods, important updates compete with routine noise.

Prioritising messages, using clear labels for urgency, and limiting channels helps teams focus on what matters now, instead of sorting through clutter while work continues at full speed.

7. Noisy work environments that hinder message delivery

On loud production lines, verbal instructions break down quickly. OSHA notes that prolonged exposure to noise above 85 decibels is common in manufacturing environments and increases safety and communication risks (Source: OSHA).

In these conditions, instructions are misheard or skipped. Shift critical communication to visuals like colour codes, photos, short videos, and mandatory read-back checks for safety and quality updates.

8. Messages shared without confirmation of receipt

Sharing updates without confirming understanding creates false confidence. Teams assume alignment while instructions go unseen or misunderstood. Simple confirmation steps, read-backs, or supervisor acknowledgements ensure critical messages land.

This is especially important for safety changes, quality alerts, and schedule shifts that cannot rely on passive visibility alone.

9. Critical updates delayed by manual approval chains

When every update waits for multiple approvals, crews rely on memory and workarounds. The Project Management Institute reports 30% of project failures stem from ineffective communication (Source: PMI).

In the manufacturing industry, delayed decisions disrupt schedules and safety. Manufacturing businesses need faster guardrails to protect effective communication across the manufacturing sector.

10. Temporary and contract workers excluded from key updates

Contract and temporary workers are often left out of critical updates due to access limitations or assumptions. This creates safety risks, quality gaps, and uneven execution.

Providing shared access points, role-based updates, and clear onboarding communication ensures everyone on the floor operates from the same expectations, regardless of employment type.

11. Fragmented communication across multiple disconnected channels

When updates live across emails, boards, chats, and verbal briefings, teams chase the “latest” version. McKinsey found employees spend up to 20% of their workweek searching for information (Source: McKinsey).

This fragmentation weakens effective communication in the manufacturing industry, especially for manufacturing businesses scaling operations across the manufacturing sector.

12. Communication gaps causing misaligned production schedules

Production schedules depend on timely updates during planning, changeovers, and exceptions. When communication breaks, teams prepare the wrong runs or miss adjustments.

This creates last-minute scrambling, rushed setups, and avoidable downtime. Clear shift briefs, visible schedules, and defined escalation paths keep execution aligned and predictable across operations.

13. Incident and issue reporting delayed or inconsistent

Shift reporting breaks when people doubt it leads anywhere. Deloitte found 80% of frontline employees say their company provides few connection opportunities at work (Source: Deloitte).

That disconnect slows incident reporting and learning. Make reporting lightweight: QR forms, photo capture, auto-routing, and a daily “you said, we did” recap by area.

14. Cultural and language differences across frontline teams

Manufacturing teams often span multiple languages, literacy levels, and cultural norms. When instructions rely on dense text or verbal explanations, meaning shifts fast.

Teams may follow different interpretations of the same directive. Using visuals, icons, translated summaries, and peer support helps ensure intent survives noise, speed, and pressure across shifts.

15. Unclear or missing communication protocols

When it is unclear who shares updates, where they are posted, or how urgent messages are escalated, communication becomes inconsistent. Teams guess which instructions matter most.

Clear protocols defining ownership, channels, timing, and confirmation expectations reduce confusion and stop supervisors from manually correcting issues that should never occur.

Assess manufacturing workforce communication challenges with

15 targeted questions

Download now

Left unaddressed, these communication challenges do not stay isolated. They ripple through daily operations, decision-making, and relationships on the floor.

To understand why fixing them matters, it helps to look at the real, measurable impact they have on performance, safety, and morale.

Impact of manufacturing workforce communication challenges

Manufacturing communication challenges are like running a line with a slightly miscalibrated sensor: the output looks fine at first, then defects stack up fast. Communication issues in factories work the same way.

Small misses in workforce communication in manufacturing spread across shifts, roles, and tools, and the damage shows up later, in costly places.

- Quality slips before anyone notices: Frontline communication in manufacturing breaks down, so teams follow old specs or miss defect patterns. Without manufacturing frontline engagement best practices, the result is repeat rework, higher scrap, and more “why did we do it this way” debates.

- Safety risks increase in quiet ways: Communication issues in factories delay hazard updates and near-miss learnings. When one shift does not hear what the last shift learned, small risks repeat. A weak manufacturing leadership engagement framework leaves supervisors chasing basic clarity instead of preventing incidents.

- Schedules wobble, and firefighting grows: Workforce communication in manufacturing fails during changeovers, so setups start wrong and plans get rewritten mid-shift. Without consistent leadership cues, teams rush, shortcuts creep in, and delays feel personal instead of process-driven.

- Morale drops, then attrition follows: Factory worker morale improvement becomes harder when people feel blamed for bad inputs. When leaders ask how to improve morale in factory workers, the answer often starts with clearer handoffs and fewer surprise changes.

- Managers turn into human routers: Without clear systems, supervisors spend hours relaying updates, confirming receipt, and translating intent. That leaves less time for coaching, problem-solving, and building trust where it actually matters.

- Feedback becomes a black hole: Weak employee feedback processes in manufacturing plants make it unclear what got fixed and what got ignored. People stop raising issues, and small problems become normal because nobody expects action.

When you understand the impact, the next step is practical. In the next section on How to improve factory worker morale through better communication, we will map simple message habits and frontline routines that make clarity visible, consistent, and repeatable.

How to improve factory worker morale through better communication

How to improve morale in factory workers is like tuning a machine after a rough run: you do not overhaul everything, you fix the small parts that cause daily friction. When shift handover communication is clean, and information sharing in manufacturing teams is consistent, manufacturing employee engagement rises because people feel informed, safe, and valued.

- Encourage open communication: Make it easy to raise issues without drama. Use quick huddles and simple channels so production team communication problems surface early, not after scrap or shutdowns hit. This supports manufacturing manager effectiveness and engagement on the floor.

- Show appreciation: Recognise effort in the moment, not months later. Tie praise to a clear action, and morale improves because people see what “good” looks like and feel noticed. Consistent recognition also helps reduce absenteeism in the manufacturing workforce.

- Improve working conditions: Fix the basics that block good work. Clear signage, safer layouts, and predictable updates strengthen manufacturing safety communication and make measuring engagement across manufacturing shifts more reliable and actionable.

- Collect feedback: Run short pulses that ask one question per week. Close the loop fast, so suggestions turn into visible changes. This builds trust, sharpens manufacturing workforce engagement metrics, and proves feedback leads to action.

(Source: Gallup)

- Celebrate employee milestones: Mark attendance streaks, certifications, and anniversaries in shift-start briefings. Small public moments build belonging and support, reducing absenteeism in manufacturing workforce over time.

- Invest in employee growth: Share clear skill paths and training schedules. When people know what comes next, shift handover communication improves because teams plan better and take ownership.

- Build team trust: Keep messages consistent across leaders and shifts. When updates do not change by person, information sharing in manufacturing teams becomes smoother and daily stress drops.

Better communication needs a system, not just good intentions. Next, we will cover how CultureMonkey improves communication in manufacturing teams using structured updates, pulse feedback, and shift-ready tools that keep messages consistent across every line.

How CultureMonkey improves communication in manufacturing teams?

Communication in modern manufacturing is like installing a clear signal tower across a noisy site: once it is steady, every message travels intact. CultureMonkey works the same way. It replaces scattered updates with structure, so communication breaks are reduced, managers act faster, and employees understand priorities clearly, regardless of physical location or shift.

- Centralised communication tools for manufacturing: CultureMonkey gives one source of truth on the manufacturing floor. Updates, alerts, and employee surveys live together, helping reduce communication gaps in factories and ensuring employees feel aligned with values, safety expectations, and production priorities.

- Improve manager communication in manufacturing: Production managers share clear updates without chasing people. Structured nudges, read receipts, and role-based targeting help manufacturing managers' effectiveness and engagement, so supervisors spend less time relaying messages and coaching teams on the plant floor.

- Employee feedback in manufacturing workplaces: Two-minute pulses capture real issues where work happens. Regular employee feedback highlights workforce challenges early, supports manufacturing workforce motivation techniques, and gives leaders practical tools to act before safety risks or frustration grow across shifts.

- Designed for the physical location reality: CultureMonkey works where email does not. QR codes and text message access fit the manufacturing floor, helping employees understand updates instantly and reducing communication breaks caused by distance, noise, or shift boundaries.

- Stronger employee retention through alignment: When messages are consistent, employees feel aligned with company values and expectations. Clear information sharing in modern manufacturing lowers confusion, improves trust in leadership, and directly supports employee retention across production teams' operations.

- Closing the loop with action, not noise: Results from employee surveys turn into visible follow-ups. Production managers see patterns, act faster, and prove feedback matters, helping reduce communication gaps in factories and keeping employees engaged despite constant workforce challenges.

- Multilingual communication built for diverse teams: CultureMonkey supports multilingual communication so updates, surveys, and alerts reach employees in languages they understand. This reduces misinterpretation, improves safety awareness, and ensures communication clarity across diverse manufacturing teams and shifts.

Conclusion

Manufacturing workforce communication challenges are not just messaging issues. In manufacturing companies, they directly influence safety, morale, and operational efficiency every day. When communication breaks down, gaps form between leadership intent and shop floor reality, leaving manufacturing employees confused, disengaged, or dependent on informal workarounds to get work done.

Over time, inconsistent communication erodes trust, slows decision-making, and weakens even well-designed processes across the manufacturing sector. The cost shows up in rework, safety risks, attrition, and leadership time spent fixing avoidable problems.

This is where CultureMonkey plays a critical role. Instead of replacing existing communication channels, CultureMonkey helps organisations understand how communication is experienced by employees. Through structured listening, employee feedback, and engagement insights, leaders gain visibility into what is landing, what is unclear, and where action is needed.

Managers communicate with greater confidence, employees feel aligned with expectations, and manufacturing companies build safer, more engaged, and more resilient teams.

Book a demo with CultureMonkey!

FAQs

1. What causes most communication problems in manufacturing teams?

Most problems in manufacturing teams start with outdated communication systems and unclear internal communication ownership. In a noisy manufacturing environment, frontline employees miss timely communication, so team members improvise. That creates communication barriers around quality control, production schedules, and safety protocols. When manufacturing leaders lack one communication strategy, poor communication spreads across production lines and hurts overall operational efficiency.

2. How can factories reduce misunderstandings on the production floor?

Reduce misunderstandings on the factory floor by streamlining communication into one manufacturing communication system and simple routines. Use visual work instructions, checklists for production processes, and instant messaging for urgent changes. Confirm receipt during shift huddles, especially for safety protocols and quality control. Modern communication technologies also help frontline workers and frontline managers coordinate faster and keep production schedules aligned.

3. What is the best way to improve morale in factory workers?

The best way to improve morale in factory workers is consistent communication plus daily recognition. Manufacturing workers want clear priorities, timely communication, and immediate feedback, not surprises. Train managers to recognise employees for worker safety, quality control wins, and teamwork. When manufacturing leaders empower managers and keep open communication through pulses or focus groups, employee morale improves.

4. How do language barriers affect communication in manufacturing?

Language barriers create communication barriers that hide errors in manufacturing plants. Frontline workers may nod without understanding, especially when safety protocols or quality control steps change. Poor communication then shows up as rework and worker safety risks. Use modern communication tools with icons and multilingual templates. Pair it with manager training so frontline managers confirm understanding and improve communication.

5. Why do shift handovers often fail in manufacturing?

Shift handovers fail when production lines rely on memory instead of a shared log. In manufacturing plants, noise and time pressure cause details to drop, so team members start the next shift blind. That hurts quality control, delays fixes, and disrupts production schedules. Replace outdated communication systems with a handover checklist, instant messaging for exceptions, and timely communication sign-offs.

6. How can managers communicate better with frontline workers?

Managers communicate better with frontline employees when they keep messages short, repeat critical points, and verify understanding. A practical communication strategy includes manager training, shift briefs, and immediate feedback loops. Empower managers to remove blockers fast and escalate safety protocol issues without delay. When manufacturing leaders model open communication and use modern communication technologies, frontline workers stay aligned.

7. What tools help improve communication in manufacturing teams?

Helpful communication tools for manufacturing teams include a central manufacturing communication system, digital tools like mobile notifications, and instant messaging for urgent changes. Real-time data sharing through the industrial internet helps teams communicate effectively during shift handovers. Add employee surveys and focus groups so manufacturing industry leaders can capture feedback, recognise employees, and support better communication tied to the company’s success.

8. How does better communication improve safety on the factory floor?

Better communication improves worker safety by making safety protocols clear, consistent, and easy to confirm. When frontline workers receive mobile notifications quickly and acknowledge alerts, hazards are handled early. Strong internal communication helps teams prioritise health, prevents incorrect setups on production lines, and supports safer decisions using digital tools and real-time data sharing across the manufacturing industry.

9. How to improve employee morale in manufacturing?

To improve employee morale in manufacturing, fix internal communication first. Give frontline employees and new employees timely updates on goals, changes, and production schedules. Recognise employees for quality wins and safe behaviour. Use employee surveys, focus groups, and regular check-ins so managers can communicate effectively, strengthen communication, and improve retention across the manufacturing industry.

10. What is the root cause of low employee morale?

The root cause of low employee morale is often poor communication that leaves manufacturing workers feeling unseen and misinformed. Outdated communication systems, weak communication strategies, and slow feedback erode trust. When leaders fail to communicate effectively or prioritise health and safety clarity, frustration grows. Manufacturing industry leaders must empower managers and reinforce better communication to protect the company’s success.