Anonymous employee surveys for manufacturing workforces: A practical guide for HR and plant leaders (2026)

In complex production environments, leadership rarely sees the full picture. Reports summarize output, supervisors share updates, and dashboards track numbers. But numbers do not always capture what people hesitate to say out loud.

Anonymous employee surveys for manufacturing workforces help bridge that gap. They provide a confidential channel for frontline feedback across shifts and plants. For management, this means fewer blind spots, earlier risk signals, and clearer insight into workforce sentiment that shapes smarter operational decisions.

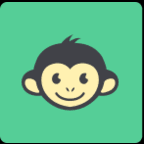

- Anonymous employee surveys for manufacturing workforces uncover safety, workload, and leadership risks that production reports miss.

- True anonymity, short surveys, and shift-friendly access increase honest participation across plants.

- Structured cadence and segmented analysis turn feedback into early risk detection.

- Visible action on results builds trust, improves morale, and supports retention.

- Platforms like CultureMonkey help protect anonymity and convert insights into measurable workplace improvements.

Why anonymous feedback matters more in manufacturing environments

In manufacturing environments, silence is often mistaken for agreement. Leaders may assume alignment across shifts and plants, even when concerns remain unspoken. Without structured listening, risks surface late and escalate quickly.

Anonymous employee surveys for manufacturing workforces create a protected channel for honest feedback. They help management identify safety gaps, workload strain, and morale shifts early, before small issues turn into operational or compliance setbacks.

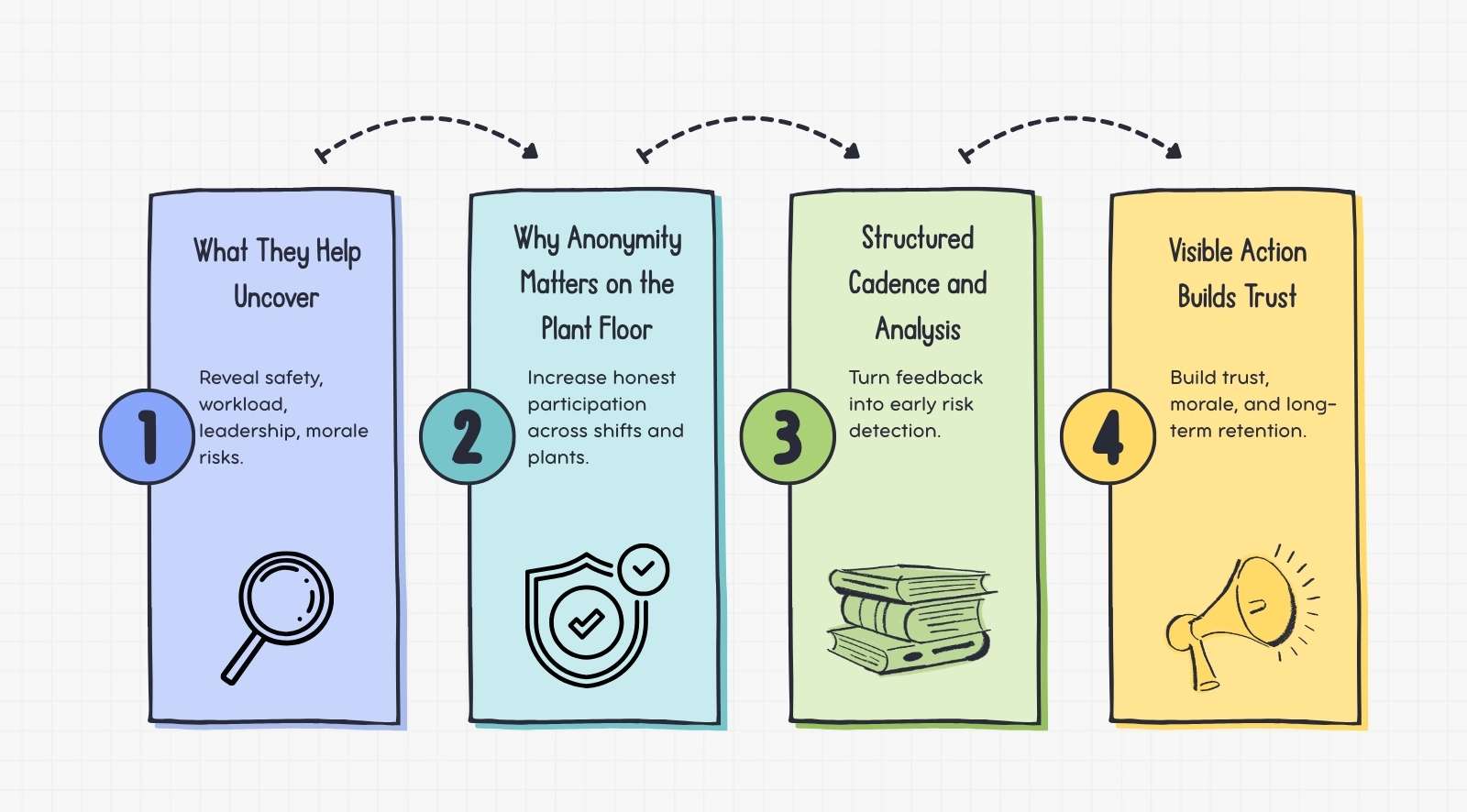

- Frontline hesitation to speak up: In plant settings, employees feel watched within tight hierarchies and may hold back honest feedback. Anonymous feedback channels increase participation in employee surveys and improve the quality of survey responses.

- Fear of supervisory consequences: When anonymous employee identity is protected, employees feel safer sharing survey feedback about workload, safety, or leadership. This strengthens employee engagement survey participation and builds more reliable survey data.

- Union and labor sensitivities: In unionized environments, open criticism can escalate quickly. Anonymous employee surveys create neutral ground, allowing honest feedback to surface without triggering defensive reactions or formal disputes.

- Unreported safety risks: Small hazards often go undocumented until incidents occur. Anonymous feedback improves survey responses around safety, giving leadership actionable survey data before issues become compliance failures.

- Production pressure overriding concerns: When output targets dominate conversations, employee engagement can quietly decline. Anonymous employee surveys capture honest feedback about fatigue and workload, helping management rebalance priorities.

- Shift and contract workforce fragmentation: Rotating shifts limits open dialogue across teams. Structured employee surveys consolidate survey feedback from diverse groups, improving visibility into employee engagement across plants.

Why manufacturing workforces hesitate to share feedback openly

In manufacturing settings, speaking up can carry perceived personal risk. Shift assignments, overtime opportunities, and supervisor relationships influence daily work experience. If feedback feels traceable, people filter what they say.

Understanding these barriers is essential before launching any survey initiative. Without strong anonymity safeguards and visible follow-through, employee feedback will remain cautious, incomplete, or surface-level.

- Fear of penalties: When comments can be linked to personally identifiable information, people expect negative consequences like shifts or lost overtime. Confidential surveys with anonymous responses reduce that fear, so survey questions capture real issues instead of safe answers.

- Distrust of confidentiality: If the survey platform asks for logins or uses the same identifiers as in previous surveys, people assume HR can trace them. In employee satisfaction surveys, survey distribution rules, third-party hosting, and no identity fields rebuild trust.

- Nothing changes afterward: When employee feedback disappears after previous surveys, people stop sharing and give short answers. Pulse surveys work when leaders show actionable feedback loops and explain what changed. That proof makes survey questions make answering and supports informed decisions.

- Manager control over shifts: When a manager can change assignments, people avoid criticism in open forums. Anonymous responses inside a neutral survey platform reduce that risk. With survey distribution across shifts, patterns surface without pointing at individuals, keeping answers safer.

- Shop-floor hierarchy: In command structures, speaking up can feel like challenging rank. If survey questions hint at names, roles, or personally identifiable information, people soften the truth. Confidential surveys remove that pressure and help leaders hear what is blocking work.

Where anonymous surveys create the biggest impact in manufacturing

Anonymous surveys are most effective when they are tied to operational outcomes. They surface early warning signs in safety, supervision, workload, and morale before those issues affect output, compliance, or retention.

When anonymity is clearly communicated and protected, participation improves. This results in more accurate data, stronger engagement signals, and clearer priorities for plant and HR leadership.

- Detecting unsafe work practices: Anonymous engagement surveys surface near-misses and unsafe shortcuts without identifying information. When data collected stays free of ip addresses and names, people report early. That improves accurate data and data quality, so leaders can act before incidents repeat.

- Identifying supervisor behavior issues: People share what they experience when identity protection is real. Remove demographic data that narrows identity and avoid collecting ip addresses. The result is better employee satisfaction signals and actionable insights, without turning feedback into a personal blame game.

- Tracking morale across shifts: Pulse-style engagement surveys capture patterns across teams and shifts without exposing identity. Keep data collection minimal and explain what data is collected. This makes responses steadier and gives accurate data to spot where morale drops first.

- Understanding attrition drivers: Anonymous surveys help collect feedback on why people leave, without forcing names or identifying information. When you communicate anonymity clearly, the data quality improves. That makes actionable insights easier to turn into retention actions and positive change.

- Capturing contract worker concerns: Contract workers often worry about how feedback travels. Use identity protection that avoids demographic data. Then collect feedback on safety, training, and treatment. You get accurate data that leadership can act on without risking trust.

- Spotting workload or machine reliability pain: People report strain and recurring breakdown issues when identity is protected. Keep data collection focused on what happened, not who said it. Strong data quality plus actionable insights help prioritize fixes that drive visible positive change.

How to design anonymous surveys for manufacturing workforces

Survey design directly impacts participation and data quality. In manufacturing environments, long forms, complex logins, or unclear intent reduce response rates immediately.

Effective anonymous surveys are short, accessible across shifts, and structured around practical workplace themes. The goal is to collect usable insights quickly without disrupting production flow.

- Keep it 5–10 questions: Short surveys reduce drop-offs and raise honest responses. Ask only what helps address concerns, job satisfaction, and employee morale. Fewer items also improve data clarity, so you can analyze data faster and get meaningful data.

- Make it mobile-first: If the survey process works on any phone, you remove friction. That improves honest responses across shifts and helps you measure organizational health. Mobile access also supports follow-up by making repeat pulse check-ins easy to run.

- Use QR codes on shop floors: QR entry removes logins and supports complete anonymity. People scan, respond, and move on. It increases genuine feedback on management practices, safety, and job satisfaction while keeping the survey process fast and consistent.

- Offer kiosks for shared access: Shared devices help teams without personal phones participate. Set rules that protect complete anonymity and keep the flow quick. This widens coverage, improves workplace dynamics visibility, and gives meaningful data on employee morale and management effectiveness.

- Support multilingual delivery: Language gaps reduce honest responses and distort survey results. Offer local languages so people can explain issues clearly. It improves workplace dynamics understanding and gives leaders meaningful data to address concerns without relying on supervisors to translate.

- Target under 2 minutes: Fast surveys protect participation during busy shifts. Short completion time increases honest responses and helps you track organizational health weekly. When you can analyze data quickly, follow-up becomes timely, and management practices improve faster.

Design is only half the win. The real trust signal is what happens next. Analyze data, share what you heard, and follow up with visible actions. That is how you improve workplace dynamics, strengthen management effectiveness, and prevent exit surveys from being your first warning.

Ensuring true anonymity in manufacturing surveys

Anonymity must be engineered, not assumed. If employees believe their responses can be traced, honesty drops, and results become distorted.

Clear safeguards such as response thresholds, aggregated reporting, and zero identifying fields are critical. When anonymity is credible, feedback becomes more candid and decision-ready.

- Set minimum response thresholds: Don’t report results until enough people respond, so individuals remain anonymous. This reduces guesswork, supports open communication, and improves data trust. It also keeps workplace dynamics safe while still surfacing valuable insights for organizational improvement.

- Avoid identifying data collection: Don’t ask for names, IDs, or fields that can link responses. Even a simple web link should not capture identity clues. Less personal detail drives unfiltered feedback, better workplace culture visibility, and more honest insights.

- Use aggregated reporting only: Share results at group level, not person level, so managers can’t single anyone out. Aggregation encourages candid feedback and reduces social desirability bias. It also supports healthier workplace dynamics while giving leaders valuable insights they can act on.

- Report at department or shift level: Share insights by line, shift, or department only when groups are large enough. This helps emphasize anonymity and keeps teams willing to speak. Done right, it improves workplace culture, highlights friction points, and enables organizational improvement.

- Prevent small-group exposure: If a segment is too small, roll it up into a bigger group to keep people safe. This protects those who want to remain anonymous, maintains open communication, and keeps unfiltered feedback flowing without fear of being traced.

- State the survey’s purpose upfront: Tell people the survey’s purpose is organizational improvement, not inspection. Say you won’t link responses to individuals. When leaders emphasize anonymity clearly, they reduce social desirability bias and get more honest insights.

Best anonymous survey questions for manufacturing employees

The quality of insights depends on the quality of questions. Generic or vague prompts produce neutral answers that offer little operational value.

Effective survey questions are specific, measurable, and tied to real manufacturing conditions. They should surface safety concerns, leadership behaviors, workload strain, and communication gaps without exposing identity.

- Safety and work conditions: Ask: “I feel safe performing my work duties.” Then add: “What makes it unsafe, if anything?” This keeps the answers concrete. It also helps you spot repeat hazards by shift or area, not just overall averages.

- Equipment and tools reliability: Ask: “Equipment and tools are reliable.” Follow with: “Which tools fail most often and when?” This pulls useful details without blaming anyone. It also highlights where downtime, rework, or unsafe workarounds may be starting.

- Supervisor fairness: Ask: “My supervisor treats workers fairly.” Add: “What does fair look like on your shift?” This turns feelings into examples. You get clearer signals on consistency, favoritism concerns, and whether people avoid speaking up around certain leaders.

- Respectful handling of concerns: Ask: “Concerns are handled respectfully.” Then ask: “What happens after you raise an issue?” This captures the real experience, not the policy. It also shows whether problems get dismissed, delayed, or pushed back onto the same people.

- Workload manageability: Ask: “My shift workload is manageable.” Add: “What causes overload most often?” This helps you separate staffing gaps from planning issues. It also flags hidden strain that leads to shortcuts, errors, or quiet frustration across crews.

- Rest between shifts: Ask: “I receive adequate rest between shifts.” Follow with: “What disrupts recovery time?” This surfaces scheduling patterns that look fine on paper but feel rough in real life. It also helps reduce fatigue-driven safety risk before incidents happen.

- Comfort raising concerns: Ask: “I feel comfortable raising concerns.” Add: “What stops you from speaking up?” This identifies fear points fast. It also helps you spot where trust breaks down, especially in high-pressure lines or tightly managed departments.

- Management listening to feedback: Ask: “Management listens to employee feedback.” Follow with: “What feedback was ignored recently?” This creates a clear test of credibility. It also shows whether follow-through is visible, consistent, and understood across shifts, not only by day teams.

How often should manufacturing plants run anonymous surveys?

Survey cadence should balance responsiveness with participation fatigue. Running surveys too infrequently delays risk detection. Running them too often reduces engagement and answer quality.

A structured baseline schedule combined with event-based pulse surveys allows plants to monitor trends while responding quickly to operational changes.

- Quarterly engagement checks: Run a deeper pulse every 12 weeks to spot slow trends in trust, safety climate, and workload. Keep it under 10 questions, share what changed, and rotate focus areas so people don’t feel surveyed to death.

- Post-incident feedback surveys: Within 24–72 hours of an incident or near miss, send a 3–5 question check to capture what people saw, what slowed response, and what would prevent repeats. Close the loop fast, or credibility drops hard.

- After shift or schedule changes: When rotations or break patterns change, survey within two weeks. Ask if the setup is workable, where it creates fatigue, and what needs fixing. This catches friction before it turns into attendance or safety issues.

- During production scale-up periods: When volumes ramp or new lines launch, run weekly micro pulse surveys for 3–4 weeks. Keep it 2 minutes, focus on staffing, training, and equipment readiness. You get early warnings without waiting for KPIs to lag.

- After leadership changes: New plant heads or supervisor reshuffles change daily behaviors fast. Survey 30 and 90 days in, asking what improved, what got harder, and where decisions feel unclear. This helps leaders adjust before trust gaps become the story.

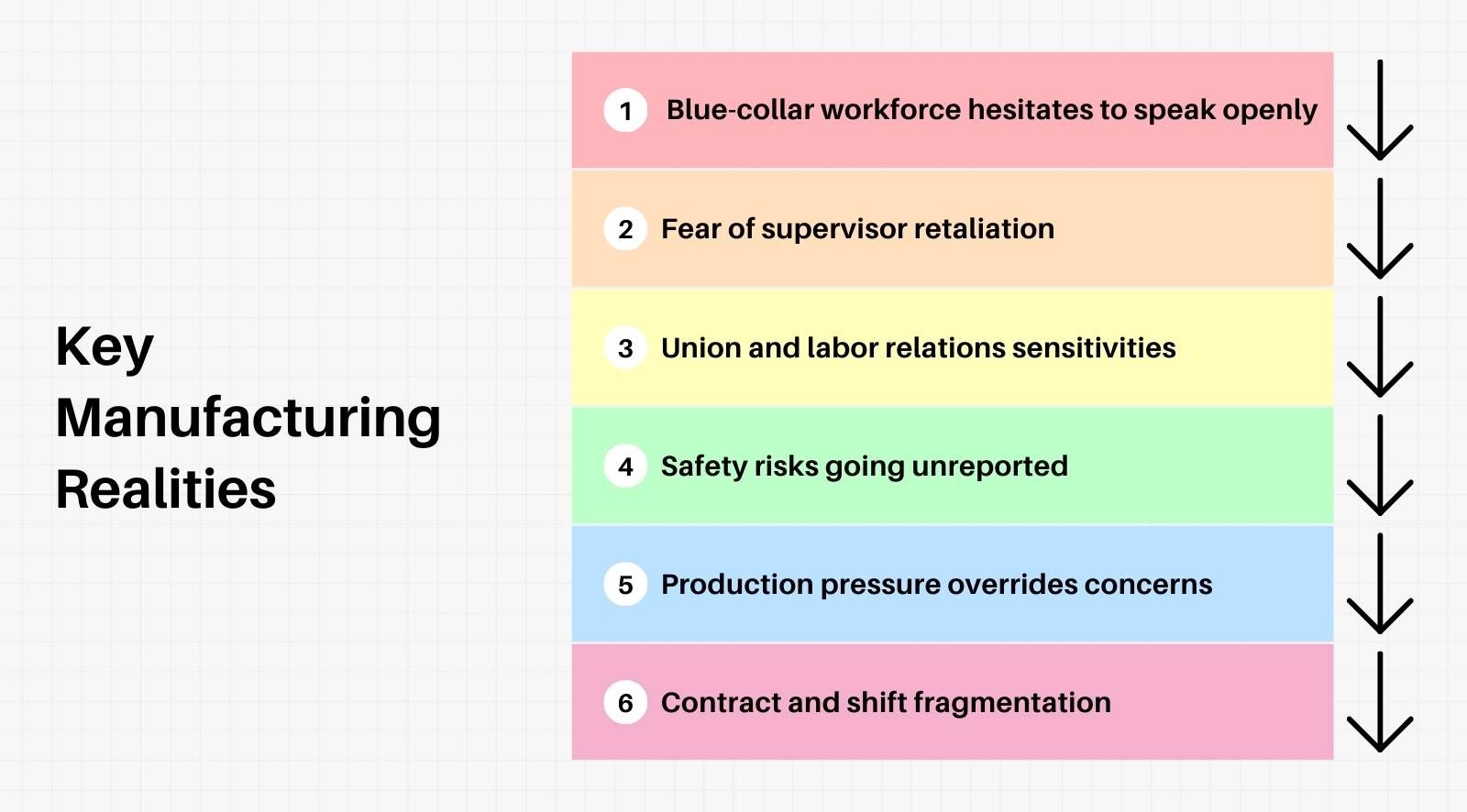

How to analyze anonymous survey data across plants and shifts

Data analysis determines whether surveys drive action or sit unused. Looking only at overall averages hides localized risk areas within specific shifts, plants, or supervisors.

Segmented analysis, trend comparisons, and correlation with operational metrics turn raw responses into practical priorities for manufacturing leadership teams.

- Compare engagement across plants: Rank plants by key themes, not just averages. Look for gaps that persist across cycles. Then ask what the high performers do differently and copy the playbook to plants where scores and comments are slipping.

- Track shift-level morale: Split results by shift and watch for patterns that repeat on nights or weekends. Morale drops often show up first in scheduling, supervisor behavior, and safety confidence. Treat shift trends as early signals, not noise.

- Identify supervisor risk areas: Group responses by reporting lines only when thresholds are met. Watch for teams with consistently low trust and high “I can’t speak up” answers. That contrast usually points to a local leadership issue, not policy.

- Flag attrition risk indicators: Create a simple risk view from workload, fairness, and “would you recommend” scores. A sharp drop plus negative comments is a warning sign. Prioritize fixes where risk clusters around one department or shift.

- Correlate safety incidents with engagement: Layer incident data over survey themes like fatigue, training, and speaking up. When engagement is low and incidents rise together, it’s rarely a coincidence. Use that link to justify action plans and resourcing.

If analysis ends at charts, nothing changes. Assign owners, set a two-week response window, and track what improved by plant and shift. That’s how survey data becomes operational action.

Turning anonymous feedback into visible workplace improvements

Survey credibility depends entirely on visible action. If employees do not see change, participation declines in future cycles.

Clear communication of findings, assigned action owners, and measurable improvements ensure anonymous feedback translates into operational and cultural progress.

- Share results with workers: Publish the top 3 themes by plant and shift, plus what will change and by when. Keep it simple, use noticeboards and WhatsApp, and repeat it in toolbox talks so nobody hears it second-hand.

- Run manager action planning: Turn each low theme into one fix, one owner, and one date. Ask managers to pick actions they can control, not policy debates. Review progress weekly so plans don’t die after the first meeting.

- Deliver safety improvements fast: Prioritize quick wins that remove hazards, fix tools, and clarify procedures. When safety feedback leads to visible changes within two weeks, participation rises. Slow responses signal that reporting risk is pointless.

- Adjust scheduling based on patterns: If fatigue, breaks, or overtime keeps appearing in comments, treat it like an operations issue. Test one scheduling change for a month, compare before and after, and keep what works across shifts.

- Train supervisors on pressure points: Use feedback themes to target coaching: fairness, respect, listening, and follow-through. Tie training to real scenarios from the floor. Then track whether the same teams report better trust in the next pulse.

If you want surveys to drive outcomes, announce two actions, complete them, and show proof. That cycle turns anonymous feedback into credibility, and credibility is what keeps responses honest.

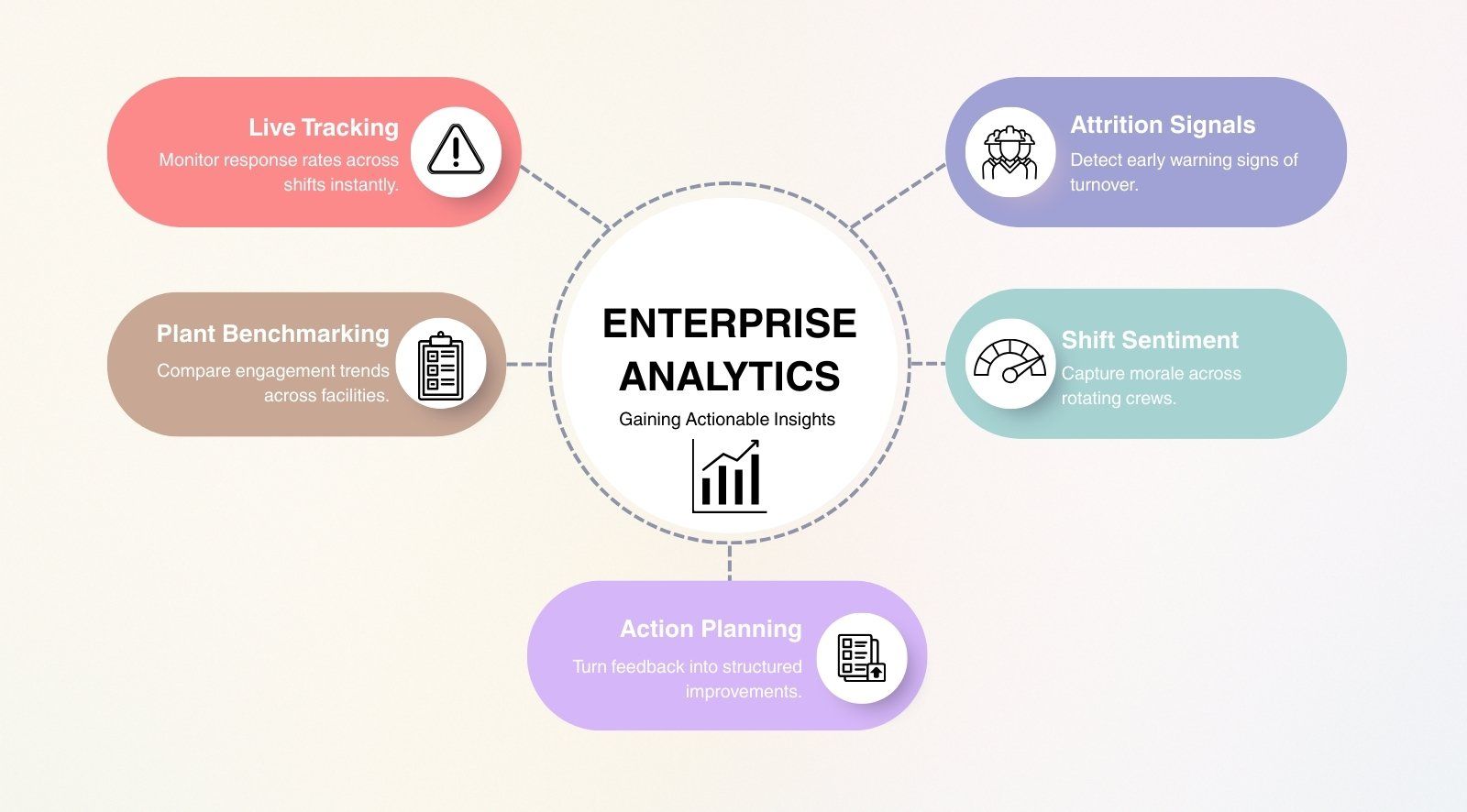

CultureMonkey’s anonymous survey software for manufacturing workforces

Selecting survey software for manufacturing requires evaluating anonymity safeguards, reporting depth, accessibility, and integration capabilities.

CultureMonkey is designed to support shift-based workforces with protected response collection, plant-level analytics, and tools that help managers act on feedback without compromising individual anonymity.

- Anonymous response protection: Look for protections that prevent managers from tracing responses. A minimum response threshold and aggregated views matter most. The goal is simple: people answer honestly, and leaders get clear signals without turning feedback into individual scrutiny.

- White label surveys: White label helps the survey feel familiar and official. It can also reduce skepticism on shop floors. Keep branding simple and avoid anything that looks like “HR tracking,” so adoption stays high across plants and contractor-heavy teams.

- Shift and plant-level reporting: Manufacturing needs reporting that compares plants and shifts without exposing small groups. Look for trend views, theme summaries, and filters that help you spot where issues start. Good reporting turns feedback into practical priorities.

- Mobile and kiosk accessibility: Plants run on shared access and fast participation. The survey should work smoothly on phones, and also support kiosk-style participation through QR codes. If access is hard, response rates drop and results become skewed.

- Multilingual support: If language coverage is limited, feedback quality suffers. Multilingual surveys help people explain issues clearly, not just pick the safest option. Better clarity leads to faster fixes for safety, scheduling, and supervisor behavior.

- Role-based data access: Role-based access keeps trust intact by limiting what different leaders can see. Plant heads need broad trends, supervisors need team-level themes, and HR needs an enterprise view. Without controls, people assume the system is traceable.

- HRIS integration: Integration helps you segment by plant, shift, and role without asking employees to self-identify inside the survey. It also reduces manual work for HR. The key is syncing structure, not personal answers.

If you’re evaluating CultureMonkey, use the same checklist. The right fit is the one that protects anonymity, works on the floor, and makes it easy for managers to act on trends without overreaching into individual-level details.

Conclusion

Anonymous listening directly strengthens safety, morale, and operational clarity in manufacturing environments. When workers trust that their identity is protected, they share honest input about risks, workload, and leadership behavior. That transparency helps management act before small issues escalate into costly disruptions.

Participation grows when employees see visible follow-through. Continuous listening builds retention, improves day-to-day engagement, and supports steady productivity across shifts and plants.

The key is consistency and credible anonymity safeguards. When evaluating engagement platforms, prioritize data protection, shift-level reporting, and frontline accessibility. CultureMonkey is designed to support these requirements while helping manufacturing leaders turn feedback into measurable workplace improvements.

FAQs

1. Are anonymous employee surveys truly anonymous?

Anonymous employee surveys are truly anonymous when no personally identifiable information is collected, response thresholds are enforced, and reporting is aggregated. Trust depends on both technical safeguards and clear communication explaining how responses are protected and who can access summarized results.

2. How do factories increase survey participation?

Factories increase participation by keeping surveys short, mobile-accessible, and available through QR codes or kiosks. Clear messaging about anonymity and visible follow-up actions also drive response rates. When workers see that feedback leads to real changes in safety, scheduling, or supervision, participation improves significantly over time.

3. Can anonymous surveys improve safety culture?

Yes, anonymous surveys can strengthen safety culture by surfacing near-misses, unsafe shortcuts, and reporting barriers early. When workers feel protected, they share candid insights about hazards and fatigue. Acting quickly on these signals reinforces psychological safety and encourages proactive reporting before incidents escalate.

4. How often should plants run engagement surveys?

Most manufacturing plants benefit from quarterly engagement surveys combined with event-based pulse checks after incidents, leadership changes, or scheduling shifts. This balanced cadence captures trends without causing fatigue. The key is responding within weeks, not months, to maintain credibility and participation quality.

5. Can surveys reduce manufacturing attrition?

Anonymous surveys can reduce attrition by identifying workload stress, supervisor behavior issues, and trust gaps before employees disengage. When leadership addresses these drivers visibly and consistently, retention improves. Continuous listening creates a feedback loop that stabilizes morale and reduces preventable turnover across plants and shifts.