9 Practical strategies to close communication gaps in supply chain teams

Have you ever watched a group of friends try to split a dinner bill without one person reading it out loud? Someone counts the starters, another remembers only their dessert, someone else rounds off “roughly,” and suddenly the total makes no sense. Everyone had access to the bill, yet no one shared the same understanding of it. The confusion is not loud, but it lingers.

That exact dynamic plays out in communication gaps in supply chain teams. Information is available, updates are sent, and tools are in use, but context travels unevenly. Small assumptions replace clarity, and alignment slips quietly between handoffs.

From a management viewpoint, this is rarely about capability. It is about how information flows, who sees it, and when. When communication fragments, even stable supply chains begin to feel harder to control than they should.

- Small misalignments, not lack of effort, cause most coordination failures across shifts, tools, and handoffs.

- Fragmented updates and unclear ownership turn routine variance into delays, rework, and frustration.

- Poor information flow weakens trust, increases second-guessing, and quietly drains energy on the floor.

- Consistent handovers, clear protocols, and feedback loops reduce noise and prevent repeat issues.

- Strong communication systems turn daily signals into shared clarity, faster responses, and steadier execution.

Why communication gaps are so common in supply chain and logistics operations

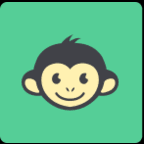

Communication gaps in supply chain teams are common because information moves faster than alignment. Updates cross shifts, systems, and partners daily. In shift-based supply chain teams, context thins out with every handoff, creating persistent communications pain points.

Another cause is fragmented communication across tools and roles. Warehouse and supply chain teams rely on chats, emails, dashboards, and calls, often without a clear owner. Supply chain professionals then interpret the same update differently, weakening supply chain management decisions across the supply chain network.

Finally, frontline signals rarely travel upward in time. Frontline supply chain teams see delays, damages, and shortages first, but planning reacts late. This disconnect affects employee engagement, leaves engaged employees unheard, and turns normal variance into visible supply chain disruptions.

Communication gaps that disrupt supply chain performance

In distributed supply chain teams and night shift logistics teams, accurate and timely information can slip between tools and handoffs. That is when communication challenges stop being annoying and start hurting results.

- Missed shift handovers: Night shift logistics teams hand over partial notes, so the next crew works with gaps. Small misses become repeat rework. These hit operational efficiency, raise training costs, and block operations from running smoothly during peak windows.

- Conflicting versions of “the truth”: Distributed supply chain teams see different dashboards, chats, and tickets. People act fast, but on different facts. The result is mispicks, wrong dock priorities, and avoidable delays that reduce customer satisfaction and strain smooth operations.

- Exceptions flagged too late: Frontline engagement in logistics drops when teams report issues and hear nothing back. Late escalation turns minor variance into firefighting. This drives engagement challenges in supply chain teams and weakens employee experience in supply chain over time.

(Source: Retail Dive)

- Unclear ownership during disruptions: When supply chain disruptions hit, “someone” is expected to respond, yet no name is clear. Tasks bounce between teams. This slows recovery, increases overtime pressure, and chips away at employee morale in the logistics industry.

- Training gets repeated, not reinforced: New hires learn through word-of-mouth because updates are scattered. Every team teaches it differently. That inconsistency drives training costs up and hurts operational efficiency, especially across distributed supply chain teams.

- Feedback loops stay one-way: Teams get new rules, but their on-ground constraints do not travel upward. Frontline engagement in logistics fades, and supply chain workforce engagement becomes fragile. Over time, employee engagement in supply chain teams dips because people stop expecting action.

When accurate and timely information becomes the default, the floor feels calmer. Fewer surprises, fewer blame loops, and clearer ownership make it easier to support each other. That is why better communication directly lifts employee morale and strengthens manager effectiveness in warehouse operations.

How better communication improves warehouse morale

When warehouse communication problems drop, the floor feels calmer and fairer. That shift matters because it shows up daily, not quarterly.

- Fewer surprises on the floor: When frontline communication in supply chain is consistent, teams stay on the same page about priorities and changes. That reduces warehouse communication problems, boosts employee satisfaction, and helps an engaged workforce show up with steadier energy each shift.

- Less blame, more clarity: Clear internal communication in logistics organisations cuts logistics team communication issues during misses. People focus on fixes, not finger-pointing. This improves employee satisfaction, supports team building, and helps the business operate with fewer tense moments.

(Source: Retail Dive)

- Cleaner handoffs, calmer shifts: Communication breakdowns in logistics operations often start at shift change. Standard notes and clear escalation keep inventory management stable. As a result, ensuring smooth operations feels realistic, and supply chains continue without constant firefighting.

- Faster problem-solving with facts: Data analytics tools help teams explain what changed, not just what broke. That makes frontline communication in the supply chain practical and credible. It strengthens risk management and helps teams recover from issues without burning out.

- More trust in decisions: When updates are timely and explained, teams believe the plan is real. That reduces logistics team communication issues and improves employee engagement. Over time, an engaged workforce is built through consistency, not pep talks.

Morale lifts when communication becomes a system, not a scramble. The next step is making it repeatable across shifts, sites, and partners. These 9 strategies focus on practical logistics workforce motivation techniques that reduce communication challenges day after day.

9 Strategies for effective communication in supply chain

When they lag, confusion spreads fast. These strategies focus on improving communication, so supply chain workforce communication holds steady, even under tight deadlines.

1. Embrace technology

Use digital tools built for real-time tracking across production schedules, delivery routes, and remote teams. The right tools reduce operational issues by syncing updates instantly. Technological advancements like machine learning and advanced analytics help teams spot risks early, avoid missed deadlines.

2. Foster transparency & trust

Share changes openly across different departments, including delays, constraints, and trade-offs. Clear communication reduces anxiety around job security and lowers operational issues. When teams understand why decisions shift, employee engagement in supply chain teams rises, missed deadlines drop, and trust supports smoother execution across the supply chain.

3. Establish clear protocols

Define who shares updates, where they live, and when they must be sent. This removes a significant challenge during tight deadlines. With clear communication rules, support consistent actions, and reduce operational issues caused by assumptions between warehouse teams and management.

4. Promote open dialogue

Create simple ways for teams to raise risks without delay or blame. Frontline input improves communication before issues escalate. When diverse perspectives shape decisions, become more useful, operational issues surface earlier, and continuous improvement replaces reactive fixes.

5. Improve collaboration

Align warehouse, transport, and planning teams through short, focused syncs. Use real-time tracking to ground decisions in facts. Better cross-team communication prevents conflicting priorities and allows for quicker responses when conditions change.

6. Customise communication

Tailor updates by role so teams receive only what they need to act. The right medium supports targeted messages using dashboards. This approach improves communication, reduces noise, and helps different departments respond faster without creating new operational issues.

7. Document & act on feedback

Capture recurring communication gaps and link fixes to training programs or process changes. Advanced analytics reveal patterns behind operational issues. When feedback leads to visible action, employee engagement in supply chain teams strengthens, and communication keeps improving over time.

8. Frontline leadership communication

Train supervisors to translate plans into clear, shift-ready instructions. Using real-time tracking, leaders can flag risks early. This limits operational issues and ensures improved communication stays practical on production lines.

9. Shift handover consistency

Standardise handovers using short templates supported by the right tools. Include production status, risks, and next actions clearly. Consistent real-time tracking prevents operational issues and keeps supply chain workforce communication stable across shifts.

Access structured questions to evaluate communication across supply chain teams

Download nowEven the best strategies stall if people hesitate to speak up. Sustainable improvement comes when feedback feels safe and useful. Next, we explore building a feedback culture in logistics organisations that supports learning every day while reducing frontline attrition in logistics workforce.

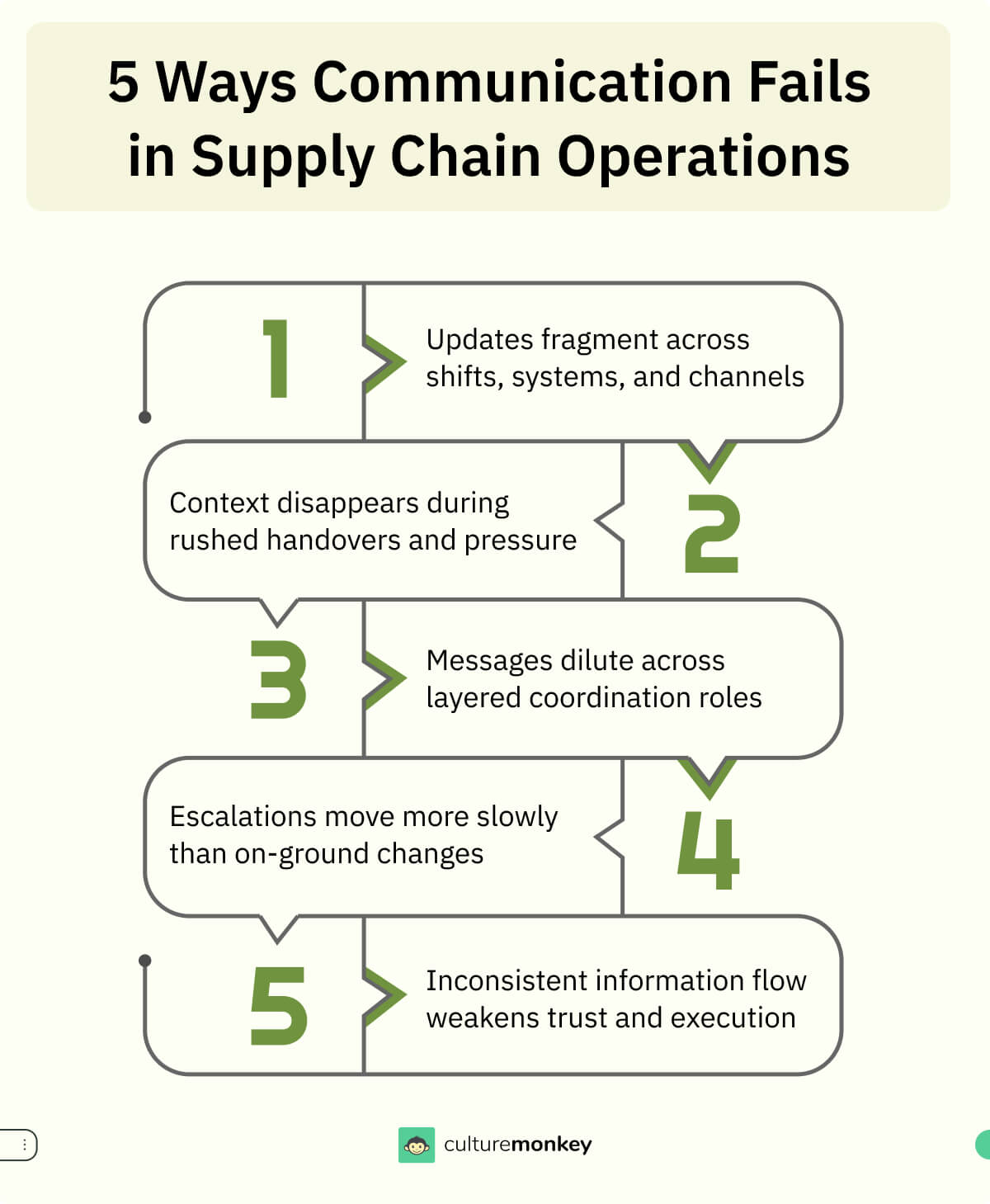

Building a feedback culture in logistics organisations to build communication

A feedback culture is like a sensor network on the floor: it catches small drifts before they become big faults. Without it, teams only react after unexpected disruptions hit inventory levels or delivery promises. When timely information flows both ways, decision-making improves and is not damaged.

- Make feedback routine, not rare: Use short weekly prompts and shift huddles so warehouse staff can flag risks fast. This creates timely information for leaders. Over time, you increase productivity, reduce unexpected disruptions, and unlock long-term benefits without adding extra meetings.

- Close the loop in public: Post “you said, we did” updates on boards and in channels so warehouse staff see action. This reveals deeper issues and builds trust. It supports a critical role in communication, which leads to repeated mistakes.

(Source: Retail Dive)

- Tie feedback to inventory signals: Ask teams what caused swings in inventory levels, not just what the numbers were. Link comments to timestamps and handoffs. This improves decision-making, preventing the timely information into practical fixes across shifts.

- Make it safe to report bad news: Reward early flags, even when they expose deeper issues. When they feel protected, timely information arrives sooner. That lowers surprise work, supports reduced costs, and delivers long-term benefits through steadier operations and clearer ownership.

- Turn feedback into development opportunities: Use patterns to coach leads and create simple training moments, not blame sessions. This improves decision-making and helps teams increase productivity. Over time, development opportunities reduce repeat errors, limit unexpected disruptions, and strengthen morale.

Once feedback creates timely information and better decision-making, you can design communication that matches how work actually flows. Next, we will translate these lessons into a practical comparison using engagement KPIs for logistics and supply chain teams to evaluate needs versus outcomes.

Choosing the right communication setup for supply chain teams: needs vs outcomes

A communication setup is like the lane plan on a packed dock. When lanes, signs, and right-of-way are clear, movement stays smooth. When they are not, operational issues multiply fast.

Employees who respect their leaders are more likely to be engaged and productive at work. Use this needs vs outcomes table to support informed decision-making in supply chain management and supply chain operations.

Once needs and outcomes are clear, execution depends on whether feedback is captured, understood, and acted on across shifts. Next, we will show how CultureMonkey enables feedback-driven communication in supply chain teams without adding noise to daily operations.

How CultureMonkey enables feedback-driven communication in supply chain teams

CultureMonkey is like a control panel that turns scattered signals into one readable dashboard. When feedback sits in pockets, supply chain team collaboration issues grow, and teams stop staying on the same page.

This section shows how a company can use CultureMonkey to set expectations, create clear expectations, and keep real-time communication practical.

- Always-on pulse listening: CultureMonkey helps collect frequent, lightweight feedback from employees across shifts, so real-time communication in logistics teams is not guesswork. This reduces supply chain team collaboration issues by surfacing friction early. Leaders can function faster.

- Anonymous feedback that feels safe: CultureMonkey supports anonymous feedback flows, which helps employees share what is really blocking work without fear. That improves well-being and keeps teams on the same page about real issues. It also helps with clearer, more trusted inputs.

- Segmentation that respects context: CultureMonkey can segment insights by team, location, and manager views, helping a company see where collaboration breaks. This makes real-time communication more targeted, not broadcast noise. Better targeting supports and creates fewer disruptions across teams.

- Manager dashboards for action: CultureMonkey offers manager-facing views so leaders can track themes and follow up with simple actions. This reduces supply chain team collaboration issues by creating ownership. When managers and employees experience clearer direction and steadier well-being.

- Action tracking and closure loops: CultureMonkey supports closing the loop by sharing what changed after feedback. This helps employees stay on the same page and builds trust in new tools. Over time, fewer disruptions and clearer expectations help retain top talent through changing demands.

- Support for change moments: When new challenges hit, CultureMonkey can run quick check-ins to understand readiness and gaps. This creates real-time communication in logistics teams that reflects reality, not assumptions. It helps a company set expectations early and reduce supply chain team collaboration issues.

Conclusion

Communication gaps in supply chain teams rarely announce themselves loudly. They show up as small delays, mixed priorities, repeated clarifications, and growing frustration across shifts and roles. Over time, these gaps affect decision-making, increase disruptions, and weaken trust between frontline teams and leadership. In complex supply chain operations, timing, handoffs, and context matter every day. It is an operational infrastructure.

Closing these gaps requires more than adding messages or meetings. Organisations need a way to listen consistently, surface issues early, and act before small signals turn into costly problems, including measuring engagement in shift-based logistics operations.

That is where CultureMonkey fits naturally. By enabling regular, safe employee feedback and clear follow-through, CultureMonkey helps organisations understand what is actually happening on the ground. This creates shared clarity, supports better decisions, and helps teams stay aligned even as supply chains grow more distributed and unpredictable.

Book a demo with CultureMonkey!

FAQs

1. What causes communication gaps in supply chain teams?

Communication gaps often come from rushed handoffs, unclear update ownership, and information spread across many channels. Employees receive fragments, not full context. As Company priorities shift quickly, operational issues appear quietly. This weakens employee engagement, disrupts smooth operations, and makes it harder for the Company to keep operations running smoothly at scale.

2. Why do warehouse teams often feel disconnected from leadership?

Warehouse floors feel distant when leadership sends decisions without the why. Employees see bottlenecks and workarounds, while dashboards hide friction. If the Company does not acknowledge that reality, employee satisfaction drops and the work environment feels unfair. Regular walkabouts, two-way updates, and shared priorities strengthen team building and keep operations running smoothly, especially during peak weeks and shift changes.

3. How do communication gaps affect morale among warehouse workers?

Morale slips when instructions conflict, priorities flip mid-shift, and questions hang unanswered. Employees start double-checking everything, then stop raising risks early. In Company sites, this delays fixes and spreads frustration. To improve employee engagement, leaders should close loops publicly, explain changes in plain words, and reinforce team building with quick huddles and recognition before fatigue becomes the default.

4. What are the biggest communication challenges in logistics organisations today?

The biggest problems are version drift, slow escalation, and unclear next steps across shifts. Employees act on different updates, so exceptions turn into operational issues quickly. Company leaders may hear fixes at industry conferences or invest in machine learning, but results lag without shared habits. Standard triggers, single-thread updates, and clear owners reduce repeat chaos.

5. How can supply chain leaders build a stronger feedback culture?

Start small: ask one focused question weekly, then publish what changed within days. Employees speak up more when they see action, not promises. Company leaders can tie themes to a workforce engagement strategy for logistics companies by assigning owners and dates. This approach lifts employee engagement, protects trust, and prevents recurring friction from becoming crises.

6. What tools help reduce communication gaps in distributed supply chain teams?

Choose systems that centralise updates, capture feedback safely, and show follow-through, not just chat volume. Employees need context attached to each change and a visible action trail. Company teams often use enterprise employee engagement tools for logistics to spot patterns and reduce operational issues. When actions are tracked to closure, the work environment steadies and smooth operations return.