20 Ways to strengthen manufacturing manager effectiveness and engagement

Manufacturing environments place unique demands on managers, requiring them to balance safety, output, quality, and workforce expectations daily. Managers operate closest to the floor, where decisions must be made quickly and communicated clearly across shifts, roles, and operational constraints. Their effectiveness directly shapes how well teams stay aligned, motivated, and responsive to change.

Manufacturing manager effectiveness and engagement are not just a leadership metric. It influences retention of skilled workers, consistency in execution, and the ability to sustain performance under pressure. As plants adopt new technologies and face tighter timelines, the role of managers becomes even more critical.

This guide outlines practical, manager-led actions that strengthen engagement without adding operational friction.

- Manufacturing manager effectiveness and engagement directly shape trust, morale, retention, safety, and daily execution on the factory floor.

- Small, consistent manager actions matter more than large programs for sustaining engagement across shifts and roles.

- Communication, fairness, visibility, and follow-through are the strongest drivers of workforce motivation in manufacturing.

- Engagement breaks down when managers lack time, structure, clear signals, or support systems.

- Practical habits, simple feedback loops, and manager enablement outperform one-time initiatives or annual surveys.

Why manufacturing managers drive workforce engagement more than any other factor

A manufacturing workforce engagement strategy is like a dashboard for a running plant: you don’t watch every part, you watch the signals. Managers sit closest to those signals. Their daily calls shape trust, clarity, and follow-through, which is why employee engagement in manufacturing shifts faster with managers than with posters or policies.

- Signal-to-action speed: Managers spot drift on the floor and correct it in minutes, not weeks. That fast loop is core to manufacturing manager engagement strategies because quick fixes protect output, safety, and morale before frustration spreads across shifts.

- Daily meaning in plain language: They translate targets into “what good looks like” for each station, every shift. Effective communication is fundamental to engaging manufacturing, and managers make it stick with brief huddles, visual cues, and one clear priority.

- Fairness people can feel: Managers control task rotation, overtime calls, and recognition in the moment, every day. When these choices look fair, employees show up with fewer grudges, more pride, and steadier teamwork across lines, crews, and shifts.

- The feedback gateway: Most ideas, complaints, and early warnings travel through one person: the supervisor. Manufacturing frontline engagement best practices work only when managers invite input, protect anonymity where needed, and close the loop fast with visible changes.

- Skill growth that sticks: Managers decide who gets cross-training, who shadows maintenance, and who leads a trial run. These manufacturing business managers' strategies to Increase Employee Engagement keep learning practical, job-relevant, and tied to the machines people actually run.

- Consistency during change: New SOPs, new tech, and new quality checks create noise and rework. Managers cut that noise by repeating the why, checking understanding, coaching the same standard, and reinforcing wins, shift after shift, until confidence returns.

Strong manufacturing manager effectiveness and engagement keep operations stable. But real-world plant conditions add friction: language gaps, rotating shifts, and constant change.

Next, we examine the common challenges manufacturing managers face when engaging manufacturing teams and the early warning signs leaders should watch for.

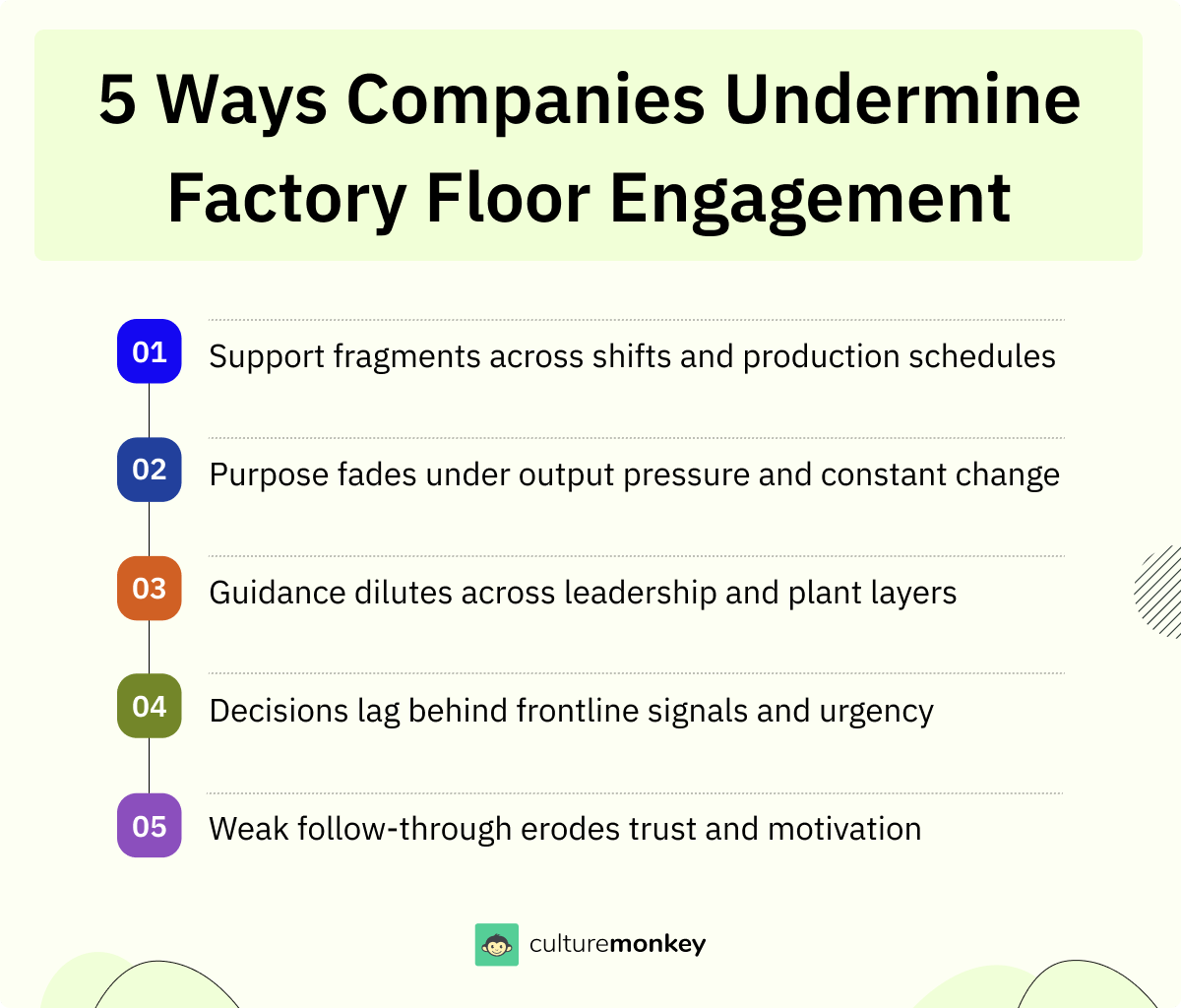

Common challenges managers face when engaging manufacturing teams

Employee engagement in manufacturing is like a safety checklist: it looks simple, but missing one step shows up fast in defects and delays. Managers feel that first. When engaged employees slip, the cause is usually daily frictions managers can’t ignore. Here are the most common blockers manufacturing companies run into.

- Shift pressure wins: When takt time is tight, managers prioritize output over conversation. Manufacturing workers get updates only when something breaks. Manufacturing leadership communication becomes reactive, so employee feedback arrives late, and small issues snowball into bigger problems.

- Shifts hide the truth: Measuring employee engagement once a year misses night crews and weekend lines. Measuring engagement across manufacturing shifts is tougher than it sounds. Without pulse checks, managers guess who is struggling, and manufacturing employee engagement turns uneven.

- Too many hats, too little coaching: Frontline manager effectiveness in manufacturing drops when supervisors chase parts, paperwork, and escalations. There’s no time left for motivating factory workers. The result is compliance without commitment, and disengaged manufacturing employees do the minimum.

- No shared playbook: Many plants lack a manufacturing leadership engagement framework, so each supervisor improvises. One line gets daily huddles, another gets silence. That inconsistency hurts business outcomes and makes it harder to improve employee engagement at scale.

- Low trust in follow-through: Manufacturing workers share employee feedback, then see no visible change. In the manufacturing industry, that creates “why bother” fatigue. Managers lose credibility, and even good ideas stop coming. It becomes harder to increase employee engagement.

- Metrics feel disconnected: Measuring employee engagement can turn into a score hunt, not a fix list. Managers see dashboards, but not what to do next. Engaged employees want actions, so manufacturing employee engagement stalls when data isn’t translated into steps.

The good news: most of these challenges are controllable with small, repeatable habits. When managers tighten communication, simplify follow-through, and measure what shifts actually feel, engaged employees rise quickly.

Next are 20 tips for increasing engagement in manufacturing.

20 Ways for increasing manager effectiveness in manufacturing

Employee engagement in manufacturing is like maintaining line balance on a complex assembly. If one station slows, everything downstream feels it. Engagement works the same way.

Small manager actions compound fast. When frontline workers feel seen, heard, and supported, manufacturing employee engagement strengthens naturally across shifts, roles, and daily routines.

1. Recognize frontline effort during active production shifts

Recognition lands best when it happens during the shift, near the machine or station. Call out safe choices, quick fixes, and steady quality in specific terms. Keep it public but brief, so it doesn’t slow the line. This builds pride, strengthens trust, and reinforces the behaviors you want repeated tomorrow.

2. Offer shift-smart flexibility without disrupting plant output

Flexibility on the floor means fair swaps, predictable rosters, and clear rules, not last-minute chaos. Publish swap windows, rotate overtime evenly, and give notice early when demand changes. When people can plan, attendance improves, and complaints drop. Managers spend less time negotiating and more time leading consistent work each week.

3. Make safety leadership a visible daily engagement signal

Make safety visible daily. Walk the area, ask one question, and fix one risk fast. When leaders treat safety as the first standard, crews relax and speak up sooner. Fewer near misses build trust. That trust fuels employee engagement because people feel protected, not policed, during every shift on site.

4. Standardize onboarding by role, line, and equipment

Standardize onboarding by role, line, and equipment so new hires aren’t guessing. Use a simple checklist: safety basics, quality points, machine start and stop, and who to call. Pair them with a buddy for the first week. Clear starts reduce early errors and prevent frustration from settling in too early.

5. Enable quick feedback from shop-floor teams

Enable fast feedback without meetings. Use QR cards, kiosk prompts, or two-question pulse surveys at shift end. Ask what slowed work and what felt unsafe. Share one action within 48 hours. When feedback becomes a habit, employee engagement improves because people see their input changing small, real things this month.

6. Design wellness programs for physical, shift-based work

Wellness has to match physical, shift-based work. Focus on fatigue, hydration, stretch routines, and ergonomic fixes at high-strain stations. Rotate repetitive tasks when possible. Make breaks predictable, not negotiated. When bodies feel supported, morale steadies, injuries drop, and teams show up more consistently across shifts even during weeks and overtime.

7. Invest in skills tied to machines and processes

Invest in skills tied to machines and processes, not generic training. Build short modules on setups, changeovers, defect spotting, and minor troubleshooting. Track who is certified for which station. When capability grows, confidence follows. Teams take ownership, reduce rework, and handle surprises without constant supervisor rescue in fast-changing production weeks.

8. Define clear advancement paths within plant roles

Define advancement paths inside plant roles, not only into supervision. Map steps like operator I to II, technician levels, lead roles, and quality champions. Show required skills and pay bands. People stay when progress is visible. Clear paths make cross-training purposeful, not random coverage work for each shift and line.

9. Ensure fair pay across shifts, skills, and roles

Pay fairness is a quiet amplifier. Audit pay across shifts, skills, tenure, and role risk. Explain differentials in plain language, and fix outliers quickly. When compensation feels consistent, gossip drops and focus returns. Fair pay supports retention, reduces absenteeism, and makes recognition feel credible rather than performative for the crew.

10. Build individualized development plans for skilled trades

Build individualized development plans for skilled trades and critical roles. Agree on one skill to deepen, one certification to earn, and one problem to lead. Review progress monthly with evidence from the floor. Personal plans show respect for expertise, reduce poaching risk, and keep plant knowledge inside for longer retention.

11. Keep HR accessible on the shop floor

Keep HR accessible on the shop floor. Set fixed walkaround times, join pre-shift huddles monthly, and offer touchpoints for sensitive issues. When support is visible, problems surface earlier and get resolved faster. Managers spend less time mediating policy confusion, and trust rises across teams, especially for contractors and new hires.

12. Foster belonging across lines, shifts, and contract types

Foster belonging across lines, shifts, and contract types. Standardize rules, rotate wins across crews, and avoid “day shift gets everything” signals. Use shared boards for updates and recognition. When people feel part of one operation, handovers improve, blame drops, and teamwork holds during demand spikes and when changes roll in.

13. Connect daily output to broader business goals

Connect daily output to broader goals, so work has context. Explain which defects drive returns, how downtime affects delivery, and why a process change matters. Use simple examples tied to customer impact. When people understand the “why,” employee engagement rises because effort feels meaningful, not just measured each shift today.

14. Use cross-training to reduce burnout and downtime

Use cross-training to reduce burnout and downtime. Build a rotation plan that spreads tough stations, backs up critical skills, and creates learning momentum. Track readiness, not just attendance. Cross-training reduces bottlenecks during absences and improves confidence during changeovers, making teams steadier under pressure without overloading the same reliable people again.

15. Enable two-way communication across plant hierarchies

Enable two-way communication across plant layers. Hold short huddles, ask one open question, and listen without arguing. Share decisions back with reasons, even when you can’t act. When messages travel both ways, employee engagement becomes durable because teams trust what they hear and what they see during audits and ramp-ups.

16. Encourage operator-led process improvement ideas

Encourage operator-led improvement ideas with a simple path: spot, log, test, share. Give small time windows for trials and protect teams from blame if a test fails. Celebrate fixes that remove friction, not just big innovations. Ownership grows when people see their ideas adopted quickly and credited to the crew.

17. Run engagement activities that fit production schedules

Run engagement activities that fit production schedules. Keep them short, tied to real wins, and timed to breaks or shift change. Use mini-contests for safety checks, quality catches, or housekeeping. When activities respect throughput, participation rises, and supervisors avoid the backlash of “extra work” that steals time from the line.

18. Improve physical and digital workplace conditions

Improve physical and digital workplace conditions to remove daily irritation. Fix lighting, signage, tool access, and missing parts workflows. Simplify logins, forms, and downtime reporting. Small frictions drain energy faster than big speeches. When the environment is smoother, teams focus on quality and safety, and managers spend time chasing basics.

19. Build inclusion across language and skill diversity

Build inclusion across language and skill diversity. Use visual standards, translated safety cues, and buddy systems for new workers. Confirm understanding by asking people to show the step, not repeat it. Inclusive communication reduces errors, raises confidence, and prevents quiet isolation that often precedes absence or exit in mixed crews.

20. Give frequent, practical feedback on work quality

Give frequent, practical feedback on work quality. Don’t wait for monthly reviews. Point to the standard, show the gap, and coach one improvement step. Balance corrections with recognition of what’s right. Consistent coaching builds competence and trust, so employee engagement deepens without extra programs, and fewer mistakes repeat across shifts.

Checklist to evaluate manufacturing manager effectiveness

Download nowStronger engagement does not rest only on the manager's behavior. Systems, tools, and leadership support matter just as much.

Next, we’ll explore how companies can support managers through structure, training, employee engagement software, pulse surveys, and top survey tools for manufacturing companies.

How can the company support managers to improve engagement on the factory floor?

Supporting frontline leadership in manufacturing is like giving a supervisor the right tools, not just higher targets. When the system is clear, managers spend less time firefighting and more time building trust. That is where manufacturing manager effectiveness and engagement improve, and where engaged workers start showing up consistently.

- Make engagement part of the job: Define key drivers, simple routines, and clear ownership for frontline employee engagement. When managers know what “good” looks like, they can boost employee engagement without guessing. It also strengthens improving manager-employee relationships in manufacturing.

- Train managers for the floor: Coaching, conflict handling, and manufacturing team engagement strategies should be trained like safety. Pair new supervisors with mentors and practical drills. It supports employee motivation techniques for factories and reduces avoidable friction across shifts.

- Give time, not just tasks: Protect 15 minutes per shift for huddles, check-ins, and employee recognition. When managers have space to lead, frontline employees feel noticed. This improves employee satisfaction and helps employee retention in a demanding manufacturing environment.

(Source: Gallup)

- Fix the basics that break trust: Broken tools, unclear SOPs, and slow maintenance approvals hurt morale fast. A safe and supportive environment starts with reliable basics. Cleaner workflows reduce safety incidents, improve safety compliance, and help to improve morale in factory workers.

- Create clear paths for career growth: Publish skill ladders, certify roles, and fund cross-training programs. When frontline employees see progress, they commit longer. This lifts employee success, strengthens employee satisfaction, and makes employee engagement important for the long haul.

- Standardize listening loops: Use employee surveys and short pulse check-ins with visible follow-through. Managers need clear themes, not raw data. Measuring engagement should produce actions that boost morale, not reports that sit unread.

- Support employee health on shifts: Provide practical recovery support: hydration, ergonomics, breaks, and rotating strain-heavy tasks. When employee health is protected, engaged workers stay steady. It also reduces absence risks and keeps teams more consistent week to week.

Managers can only lead engagement as far as the system allows. The next step is turning these supports into repeatable tools and workflows that managers can use daily. Next, we’ll cover tools and systems that help managers improve engagement in manufacturing.

Tools and systems that help managers improve engagement in manufacturing

Driving engagement on the factory floor is like running preventive maintenance. You don’t wait for breakdowns; you build routines that catch issues early. The right tools reduce manufacturing people management challenges by giving managers clear signals, simple actions, and consistent follow-through across routine tasks, shifts, and production targets.

- Pulse feedback systems: Short check-ins capture worker engagement trends from many manufacturing workers, not just the loudest voices. This supports employee morale, reduces blind spots, and helps manufacturing managers act before employee turnover or employee absenteeism shows up on the line.

- Manager communication playbooks: Simple scripts for huddles, 1:1s, and shift handovers strengthen manager communication skills in manufacturing. Better message clarity improves alignment with company goals, reduces rework, and makes the company's mission feel real during daily manufacturing operations.

- Visual KPI dashboards: Clear key performance indicators keep managers focused on the few numbers that matter. Pairing output metrics with worker engagement and employee morale helps manufacturing workforce performance management stay balanced, not purely production-driven, across production targets and safety protocols.

- Shift handover systems: Structured handover notes reduce confusion between crews and prevent “we didn’t know” moments. This lowers friction in manufacturing operations, supports safety protocols, and helps manufacturing managers maintain steady performance without repeating the same fixes every shift.

- Recognition and reward tools: Lightweight tools for timely praise help managers reinforce the right behaviors fast. Recognition tied to safety protocols, quality checks, and teamwork improves employee morale and supports manufacturing workforce motivation techniques in a practical, non-fluffy way.

- Skills and growth tracking: Role-based skill matrices and training logs make growth opportunities visible for manufacturing professionals. When people see progress, worker engagement rises. It also reduces employee turnover by showing a path forward inside the manufacturing sector.

- Absence and fatigue monitoring: Simple tracking of patterns helps managers spot early risk for employee absenteeism. Linking data to shift schedules, overtime, and workload supports fair adjustments, protects employee morale, and keeps production targets achievable without burning teams out.

- Performance check-in cadence: Short, frequent check-ins beat yearly reviews for frontline roles. This system strengthens manufacturing workforce performance management by making coaching normal, keeping expectations clear, and reducing the “only hear from you when it’s bad” feeling.

Tools create the structure, but habits create the results. Next, we’ll cover best practices to enhance manufacturing manager effectiveness over time, so these systems improve manager behavior, not just reporting.

Best practices to enhance manufacturing manager effectiveness over time

Best practices are like preventive maintenance for leadership: you do small checks often, so problems don’t turn into shutdowns. In manufacturing organizations, managers' habits shape employee experience every shift. The goal is a productive workforce that listens early, coaches consistently, and keeps engagement efforts tied to organizational objectives, week after week.

- Run weekly listening loops: Capture employee input in ten minutes, then share one action back on the floor. This keeps employee voice alive, improves employee experience, and builds trust that engagement efforts lead to real fixes, not just notes.

- Coach safety in the moment: Treat safety training as daily micro-coaching, not a yearly event. When leaders correct small risks early and explain why, teams feel protected, engagement metrics improve, and safety becomes part of business success, not a checkbox.

- Invest in leadership development sprints: Use short, role-based sessions on feedback, conflict, and clarity. Pair training with real scenarios and peer review. This raises organizational effectiveness, improves the employee experience, and keeps managers aligned to organizational objectives under pressure.

- Track leading signals, not only outcomes: Review engagement metrics alongside quality, safety, and attendance weekly. Look for drift before it hits results. This links employee voice to decisions and prevents engagement efforts from becoming a monthly report no one uses.

- Make skill building visible: Maintain a simple skill grid and celebrate progress, not just promotions. When people see a path, they stay longer. It strengthens employee experience, supports a productive workforce, and improves organizational success through deeper capability.

- Tie recognition to the mission: Praise behaviors that protect organizational objectives: safe handoffs, quality checks, and helping others. This boosts engagement without gimmicks. Consistent recognition builds business success by reinforcing what “good work” looks like in practice, every shift.

- Close the loop on changes: After you act on employee input, show the before-and-after in simple words. When teams see movement, they speak up more. This improves engagement metrics, strengthens employee voice, and supports organizational success without extra meetings.

These practices compound when managers have one place to gather employee voice, track engagement metrics, and share actions back to teams consistently. Next, we’ll look at how CultureMonkey supports effective manufacturing managers and engaged teams.

How CultureMonkey supports effective manufacturing managers and engaged teams

Supporting managers with CultureMonkey is like installing a real-time control panel beside the line, not in a distant office. Manufacturing organizations need clear signals, not noise.

CultureMonkey helps manufacturing companies turn daily input into action, so employee engagement in manufacturing improves where frontline workers operate, not where reports are reviewed.

- Always-on listening built for the floor: CultureMonkey enables employee engagement surveys and pulse surveys that reach frontline workers without disrupting shifts. These inputs strengthen employee feedback processes in manufacturing plants and provide manufacturing workforce engagement metrics managers can actually use to spot early risks.

- Clear signals managers can act on: The platform surfaces key drivers behind frontline employee engagement instead of overwhelming managers with raw data. Manufacturing companies and manufacturing organizations see patterns across frontline employees and corporate employees, helping leaders focus on actions that support company goals and improve morale on the floor.

- Designed for manufacturing realities: CultureMonkey supports employee surveys that work across plants, shifts, and access levels. Manufacturing companies use one employee engagement software to include frontline workers, reduce blind spots, and address challenges unique to the manufacturing industry.

- Turning feedback into visible action: Managers track themes, close loops, and communicate outcomes clearly. This builds trust among frontline workers, supports employee recognition in manufacturing organizations, and directly contributes to reducing absenteeism in manufacturing workforce through faster issue resolution.

- Scales across complex operations: CultureMonkey supports multiple plants under one system, helping manufacturing companies standardize frontline employee engagement while respecting local needs. Manufacturing organizations gain consistent insights, practical employee engagement ideas, and clearer ownership for how to improve morale in factory workers across teams.

Conclusion

Manufacturing manager effectiveness and engagement sit at the center of everything that happens on the factory floor. Managers translate strategy into action, shape daily behavior, and influence how teams respond to pressure, change, and uncertainty. When managers are consistent, approachable, and equipped to listen and act, teams stay aligned, motivated, and resilient. When they are unsupported, even strong systems struggle to deliver results.

This is where CultureMonkey plays a meaningful role. It helps organizations give managers clear, timely insight into how teams are actually feeling, across shifts and roles. With simple pulse surveys, structured feedback loops, and actionable insights, managers move from guesswork to informed action. Issues surface early, progress becomes visible, and trust builds through consistent follow-through.

By enabling managers to listen better, act faster, and close the loop clearly, CultureMonkey helps manufacturing organizations turn everyday leadership into sustained engagement, stronger retention, and healthier performance on the floor.

Book a demo with CultureMonkey.

FAQs

1. How to be an Effective Manufacturing Manager

An effective manufacturing manager keeps priorities simple, shows up daily, and follows through on promises. Manufacturing employees respond when decisions are fair, and coaching is practical. Use one routine: listen, act, and communicate outcomes. When employee engagement in manufacturing is treated as a daily habit, not a campaign, engaged employees become the norm across shifts and roles.

2. What makes a manufacturing manager effective and engaging?

Effectiveness comes from turning plans into repeatable habits. Teams engage when expectations are clear, tools are ready, and feedback is timely, regular. Build trust by linking daily work to company goals and by inviting employee participation in small improvements. This consistency creates engaged manufacturing employees and supports effective employee engagement strategies without adding extra meetings.

3. How do managers influence employee engagement on the factory floor?

Managers shape what people believe is safe to say and worth doing. When messages are clear, and actions match words, employees feel respected. That respect drives employee engagement in manufacturing faster than posters or incentives. Frontline workers notice fairness in assignments, responses to issues, and recognition. Over time, this builds an engaged workforce with steadier quality and attendance.

4. What motivation techniques work best for manufacturing workers?

Motivation improves when progress is visible and effort is acknowledged quickly. Offer skill paths, short coaching, and fair rotations so work stays sustainable. Manufacturing employees stick when growth feels real, not promised. Practical recognition and clear standards help create highly engaged employees. These steps can improve employee engagement without disrupting output or making rewards feel random.

5. Why do some manufacturing managers struggle with employee engagement?

Managers struggle when they are overloaded, unclear on priorities, or unsupported by systems. In the manufacturing industry, urgent targets can crowd out people's routines. When employee engagement efforts are ad hoc, manufacturing employees get mixed signals, and trust erodes. Create a simple weekly cadence for check-ins and actions, so engagement stays consistent, not reactive.

6. How does manager communication impact workforce motivation in manufacturing?

Communication affects clarity, trust, and pace. When managers explain the why, repeat key points, and close loops, teams move together. Manufacturing companies win when updates are short, consistent, and tied to outcomes. Employee engagement in manufacturing rises when feedback is acknowledged publicly and decisions are explained plainly. That reduces confusion and prevents rumors from spreading.