Pulse surveys in manufacturing environments to improve retention across plants and shifts in 2026

Pulse surveys manufacturing environments are short, frequent check-ins designed to capture real-time feedback from frontline workers, supervisors, and plant teams without disrupting production.

In factories where shifts rotate, safety risks are real, and margins are tight, waiting for annual engagement surveys simply does not work. These quick surveys help the management team understand morale, workload pressure, safety concerns, and internal communication gaps before they escalate into absenteeism or turnover and affect employee satisfaction.

When designed well, they give plant leaders clarity and meaningful insights. For operations teams, that means making better decisions from understanding the gathered insights of feedback collection.

Keep reading to see how to make them actually work on the shop floor.

- Pulse surveys manufacturing environments are short, frequent feedback check-ins across shifts and plants without disrupting production.

- They reveal shift-level gaps in safety, workload, supervision, and morale that annual surveys miss.

- Effective design means 5–8 questions, mobile or QR access, anonymity, multilingual support, and aligned cadence.

- Smart analysis compares shifts, tracks trends, and links engagement to safety and attrition metrics.

- CultureMonkey’s pulse surveys for manufacturing environments deliver multilingual surveys with shift segmentation and supervisor insights to reduce attrition.

Engagement challenges unique to manufacturing workforces

Before building pulse surveys in manufacturing environments, leaders need to understand the key drivers of pressures shaping daily work. Factory floors run on precision, speed, and safety, which creates unique engagement risks inside the workplace.

- Night and rotating shifts: Irregular hours disrupt routines, strain health, and often leave workers feeling disconnected from leadership visibility.

- Limited communication access: Shop-floor teams rarely sit at desks, so traditional email updates or intranet posts miss large parts of the factory workforce.

- Supervisor influence: Frontline managers directly shape morale, trust, and daily motivation in manufacturing pulse surveys more than corporate messaging ever will.

- Output versus well-being tension: Production targets can overshadow recovery time, increasing stress and quiet disengagement across shifts, negatively affecting employee satisfaction.

- Seasonal and contract gaps: Temporary workers may feel excluded from recognition, continuous feedback loops, and long-term workforce conversations.

Learn more about manufacturing workforce communication challenges here.

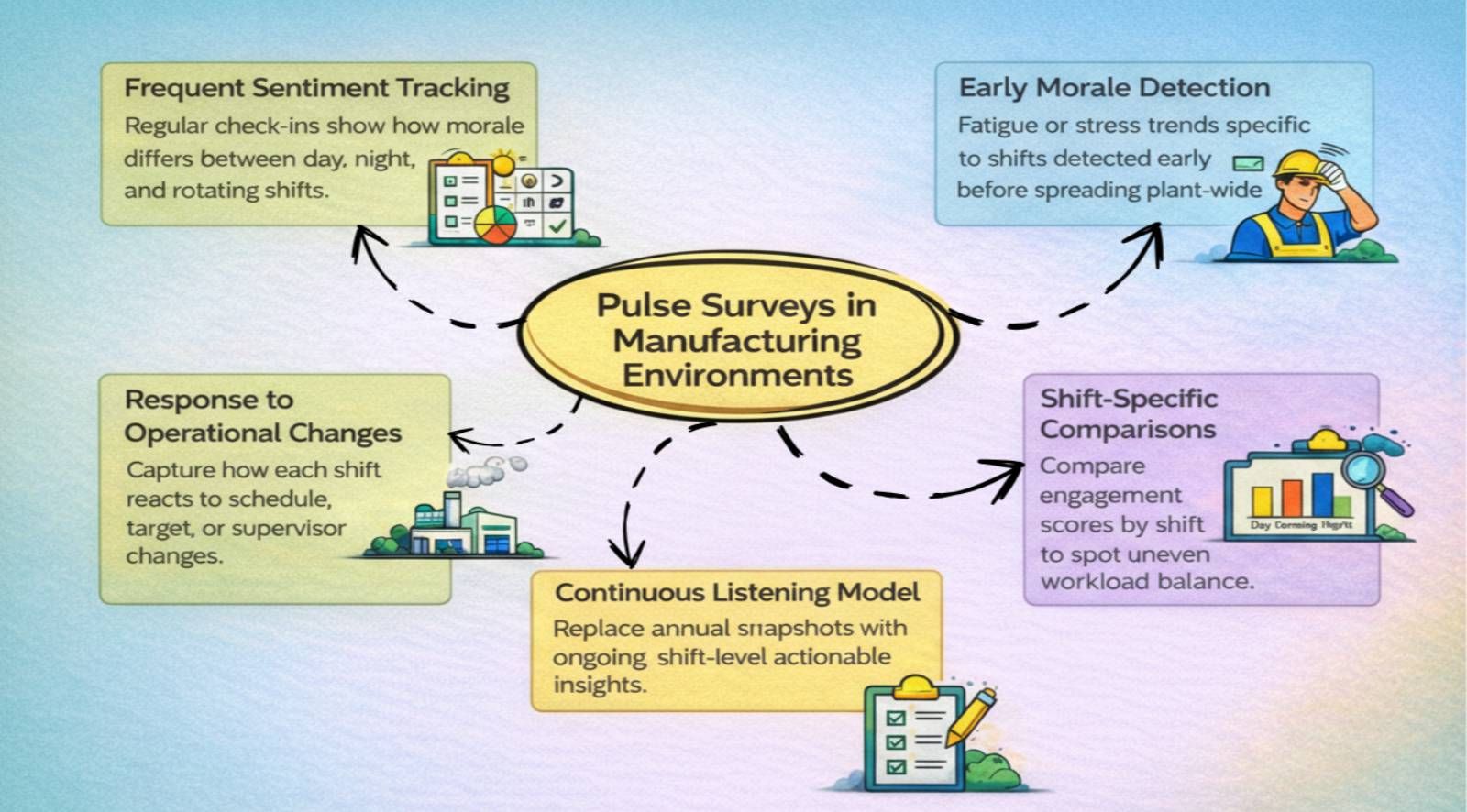

How pulse surveys reveal engagement patterns across manufacturing shifts

Shift work changes how people experience pressure, leadership, and communication inside a plant. Pulse surveys manufacturing environments help leaders see those differences clearly within the workplace.

- Frequent sentiment tracking: Regular check-ins show how morale differs between day, night, and rotating shifts instead of blending all responses together.

- Early morale detection: Manufacturing pulse surveys surface fatigue or stress trends specific to certain shifts before problems spread plant-wide.

- Shift-specific comparisons: Pulse surveys for manufacturing plants allow manufacturing leaders to compare engagement scores by shift and identify uneven supervision or workload balance.

- Response to operational changes: When schedules, targets, or supervisors change, employee pulse surveys in factories capture how each shift reacts.

- Continuous listening model: Manufacturing workforce pulse surveys replace annual snapshots with ongoing, shift-level actionable insights leaders can act on quickly.

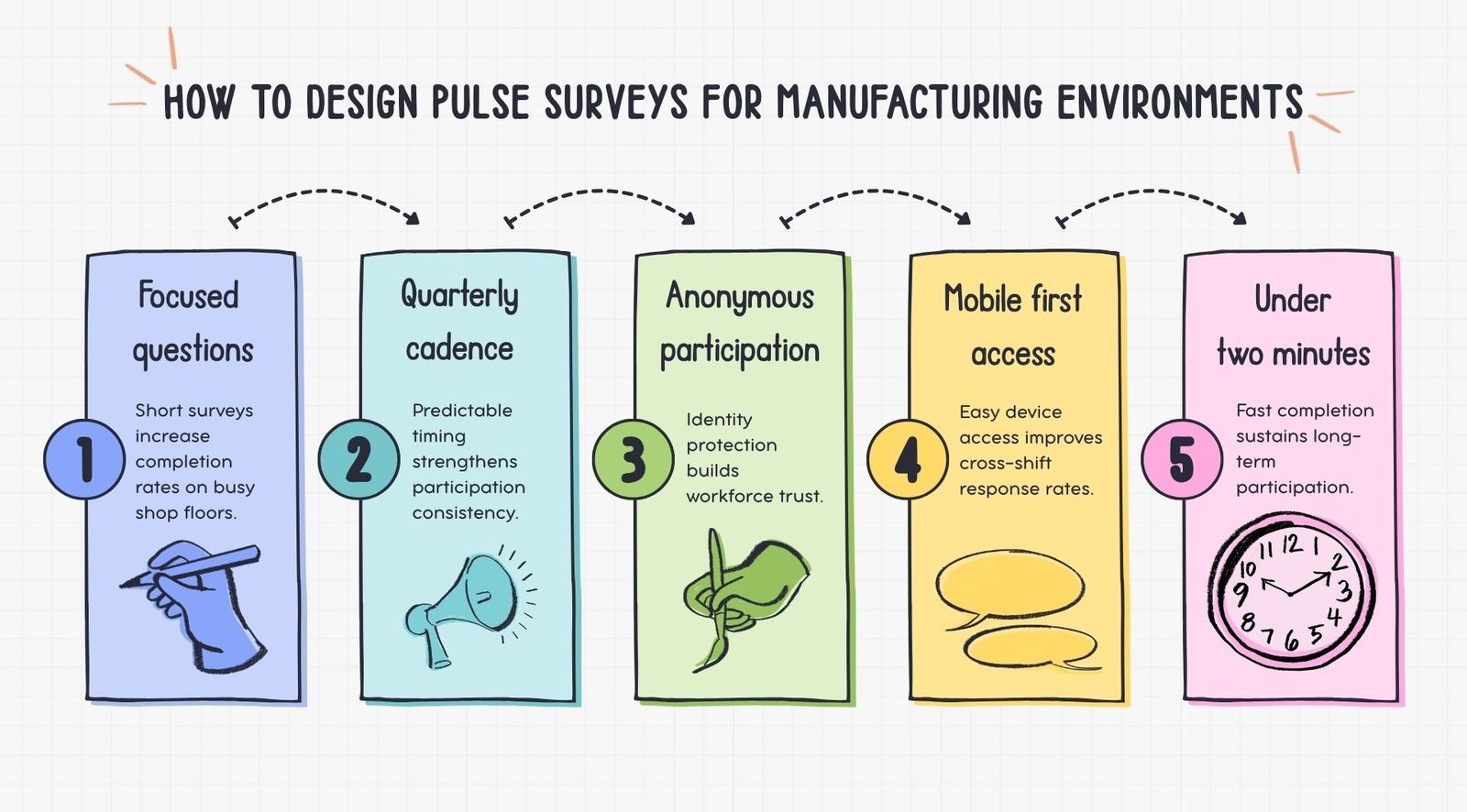

How to design pulse surveys for manufacturing environments

Pulse surveys manufacturing environments must balance production pressure, safety priorities, and frontline accessibility. Poorly designed manufacturing pulse surveys risk low participation, rushed responses, or distrust among shift workers. Employee survey design should reduce effort while increasing clarity, especially for employee pulse surveys in factories.

Core survey design principles

- Limit surveys to 5–8 focused questions: Short survey formats improve completion rates in pulse surveys for manufacturing plants where time is limited.

- Run employee surveys monthly or quarterly: Manufacturing workforce pulse surveys should follow a predictable cadence aligned with shift cycles and production reviews.

- Ensure anonymous participation: Industrial employee pulse surveys must protect identity, especially in smaller production teams to maintain employee satisfaction.

- Use mobile-first access: Pulse survey software for manufacturing should work seamlessly on shared devices and personal mobile devices.

- Keep employee surveys under two minutes: Quick completion of employee pulse surveys supports consistent participation across rotating shifts.

Survey distribution across production environments

Access and ease directly affect participation in pulse surveys manufacturing environments. Distribution methods must fit real factory workflows, not office habits.

- For quick participation during shift transitions, post QR code access in the break area.

- Shared kiosks or secured tablets positioned on the shop floor for non-desk employees.

- Improve reach for distributed or rotating manufacturing workforce pulse surveys by sending SMS survey links.

- Supervisor reminders during shift huddles without influencing responses.

- Support diverse teams using Multilingual employee pulse surveys in factories.

Practical distribution ensures manufacturing pulse surveys capture responses across all shifts, not just office staff.

Best pulse survey questions for manufacturing employees

The strength of pulse surveys manufacturing environments depends on asking clear, shift-relevant questions. Manufacturing pulse surveys should focus on safety, workload balance, supervision, and communication without adding complexity for shop-floor teams.

Safety and work conditions

Safety shapes trust and performance on the shop floor. These questions in employee pulse surveys in factories help identify risks before they become incidents.

- I feel safe performing my daily tasks on the production floor. (Strongly agree → Strongly disagree)

- The equipment and tools I use are reliable and well maintained. (Strongly agree → Strongly disagree)

- Safety concerns are addressed quickly in my work area. (Strongly agree → Strongly disagree)

- I receive clear instructions on safety procedures for my role. (Strongly agree → Strongly disagree)

Workload and scheduling

Workload balance affects fatigue, morale, and output. Manufacturing workforce pulse surveys should track pressure across different shifts.

- My workload is manageable during most shifts. (Strongly agree → Strongly disagree)

- Production targets feel realistic for my team. (Strongly agree → Strongly disagree)

- I get sufficient recovery time between shifts. (Strongly agree → Strongly disagree)

- Overtime expectations are communicated clearly in advance. (Strongly agree → Strongly disagree)

Supervisor and leadership support

Frontline supervisors shape day-to-day experience more than policy documents. Pulse surveys for manufacturing plants should reflect that influence.

- My supervisor listens when I raise concerns. (Strongly agree → Strongly disagree)

- I receive timely support when facing operational issues. (Strongly agree → Strongly disagree)

- Expectations from leadership are clear and consistent. (Strongly agree → Strongly disagree)

- I feel respected by my immediate supervisor. (Strongly agree → Strongly disagree)

Communication and trust

Clear communication prevents confusion and rumor cycles inside industrial environments. Industrial employee pulse surveys should measure transparency directly.

- Management communicates production changes clearly. (Strongly agree → Strongly disagree)

- I trust leadership decisions that affect my shift. (Strongly agree → Strongly disagree)

- Employee feedback leads to visible improvements in my department. (Strongly agree → Strongly disagree)

How often should manufacturing plants run pulse surveys?

The right cadence of sending pulse surveys manufacturing environments depends on production volatility, workforce strain, and how quickly plant conditions change. Manufacturing pulse surveys should follow operational rhythm, not a fixed HR calendar.

When to increase survey frequency

- Use monthly pulses during high operational intensity such as demand spikes, overtime cycles, or staffing shortages.

- Trigger surveys after safety events or near misses to understand shift-level confidence and process clarity.

- Run focused pulses during supervisor changes or team reshuffling to detect morale shifts early.

- Increase cadence during expansion, automation, or new line launches where uncertainty rises

- Deploy short check-ins when absenteeism or turnover trends increase on specific shifts.

Recommended survey cadence by plant situation

| Plant situation | Recommended frequency | Objective |

|---|---|---|

| High-output or rapid scaling lines | Monthly | Detect fatigue, morale shifts, and supervision gaps early |

| Stable, mature production units | Quarterly | Track engagement trends without creating survey fatigue |

| Post-safety incident or workflow change | Immediate + follow-up pulse | Measure clarity, confidence, and recovery across shifts |

| Workforce restructuring or seasonal expansion | Monthly during transition | Monitor workload pressure and communication clarity |

| New technology or automation rollout | Short pulse within 30 days | Identify training gaps and adaptation challenges |

How to analyze pulse survey data across plants and shifts?

Pulse surveys manufacturing environments should move beyond average engagement scores and focus on operational pressure signals, supervision quality, and safety exposure. The goal is to identify plant-level risks through factory workforce pulse surveys that affect productivity, employee retention, and compliance.

Effective analysis of employee engagement levels combines plant segmentation, shift comparison, trend tracking, and correlation with real operational metrics.

Compare engagement across shifts

Shift-based reporting of employee engagement survey results reveal hidden strain patterns masked by plant-wide averages. Without segmentation in industrial employee feedback softwares, these differences disappear in aggregate reporting.

Analysis should:

- Collect feedback and compare engagement scores across day, night, and rotating shifts.

- Track workload and recovery-time signals within overtime-heavy teams.

- Identify shifts where supervisor ratings consistently underperform plant averages.

Persistent shift-level gaps frequently predict fatigue-related safety exposure and voluntary turnover.

Identify morale differences by shifts

Morale can vary sharply across shifts because workload peaks, supervision style, and communication access change. Shift-level morale analysis of employee engagement survey results can pinpoint where the experience breaks.

Leaders should:

- Compare morale indicators like employee recognition, fairness, and “I feel heard” across each shift.

- Track whether overtime-heavy shifts show sustained drops in energy and recovery time scores to make informed decisions.

- Flag shifts where morale decline aligns with higher absenteeism, quality issues, or incident reports.

This helps leaders fix the right shift conditions instead of launching generic engagement programs and improving employee satisfaction.

Detect supervisor-level risk zones

Supervisor influence becomes measurable when manufacturing workforce pulse surveys are filtered by reporting lines. Supervisor segmentation in employee engagement survey results transform abstract engagement trends into actionable coaching priorities.

Leaders should:

- Compare supervisor trust and support scores across teams.

- Monitor units with repeated low clarity or respect indicators.

- Cross-check supervisor-level results with attrition or absenteeism spikes.

Early supervisor intervention prevents isolated team strain from spreading across production units.

Track engagement trends over time

Trend analysis within pulse survey software for manufacturing highlights gradual workload strain, declining trust, or recurring communication breakdowns. Rolling comparisons in factory workforce analytics softwares provide stronger signals than static snapshots.

Effective trend tracking includes:

- Monitoring quarter-over-quarter movement in workload and safety confidence.

- Identifying departments with consistent downward drift across cycles.

- Validating improvement after operational adjustments or leadership changes.

Sustained decline patterns in employee feedback often precede turnover acceleration and performance instability.

Correlate engagement with safety and retention metrics

Engagement data of employee feedback should be integrated with incident reports, absenteeism levels, and voluntary attrition across plants and shifts. Correlation analysis converts perception data into operational forecasting.

Recommended correlations include:

- Workload pressure vs safety incident frequency.

- Supervisor trust vs team-level attrition trends.

- Recovery time scores vs sick leave patterns.

When morale decline aligns with safety or retention deterioration, intervention becomes evidence-driven rather than assumption-based.

Using CultureMonkey pulse surveys to reduce attrition in manufacturing environments

Manufacturing teams operate under production pressure, safety risk, and shift-based complexity. CultureMonkey's effective pulse surveys are built for gathering employee feedback to fit these realities, giving plant leaders clear visibility without disrupting operations.

- Shift-level segmentation and reporting highlights whether night shifts show higher fatigue, lower trust, or heavier overtime strain than day teams in manufacturing companies.

- AI-driven trend analysis across cycles detects gradual burnout signals during peak production seasons or sustained overtime periods.

- Supervisor-level heatmaps and team comparisons reveal production lines where leadership behavior drives silent disengagement.

- Plant-level and multi-location benchmarking dashboards expose facilities where engagement drops coincide with rising operator exits.

- QR-based survey access on the shop floor ensures machine operators and technicians participate without disrupting output in manufacturing companies.

- Multilingual survey support captures feedback from contract labor and migrant workforce segments common in manufacturing plants.

- Automated pulse survey cadence scheduling aligned to production cycles prevents survey fatigue during high-output months.

.webp)

Improve manufacturing culture with smarter pulse surveys

- Multi-lingual Surveys

- Omni-Channel Distribution

- Mobile Friendly Surveys

- Enterprise Grade Security

Conclusion

In manufacturing environments, frequent listening is not a culture initiative. It is an operational safeguard. Pulse surveys manufacturing environments improve morale, strengthen safety awareness, and surface shift-level strain before it affects output.

Early insights prevent workforce disruptions by identifying burnout, supervision gaps, and scheduling pressure before resignations or incidents rise. When leaders act quickly, engagement becomes a stabilizing force across plants.

If you are evaluating a manufacturing employee engagement platform, choose one built for the factory floors. CultureMonkey, as a manufacturing employee engagement platform, helpsf

by delivering shift-level segmentation, plant benchmarking, supervisor heatmaps, and AI-driven trend detection tailored to shop-floor realities.

Book a demo with CultureMonkey.

FAQs

1. What is a pulse survey in manufacturing?

A pulse survey in manufacturing is a short, frequent employee feedback survey designed to capture real-time sentiment across shifts, production lines, and plants. It helps leaders monitor safety confidence, workload pressure, supervision quality, and morale without disrupting operations.

2. How often should factories run pulse surveys?

Unlike traditional surveys, factories should run pulse surveys monthly in high-change or high-output environments and quarterly in stable operations to collect honest feedback. Additional surveys may gain valuable insights about following safety incidents, restructuring, or major production changes to capture timely shift-level feedback.

3. How do you increase survey participation among factory workers?

Increase participation by using QR codes, providing kiosk-based pulse surveys in factories, and mobile-friendly surveys. Keep surveys under two minutes, ensure anonymity, offer multilingual access, and clearly communicate actions taken from previous feedback to build trust.

4. Can pulse surveys improve plant safety?

Yes. Pulse surveys can improve plant safety by identifying early warning signs such as fatigue, unclear procedures, or low safety confidence. Addressing these signals early reduces incident risk and strengthens compliance behavior across shifts.

5. Do pulse surveys reduce manufacturing attrition?

Pulse surveys reduce manufacturing attrition by detecting burnout, supervision gaps, and workload imbalance before employees resign. When leaders act on insights quickly, workforce stability improves and unexpected turnover decreases.