12 Step-by-step actions to measure engagement in shift-based logistics operations

At a busy airport late at night, you can tell when the flow is right. Planes land smoothly, luggage appears without chaos, and announcements feel calm. Then there are nights when nothing is technically wrong, yet everything feels strained. Bags arrive more slowly. Small delays stack up. The system is moving, but not comfortably.

That quiet tension is easy to miss unless you are responsible for keeping things running.

Shift-based logistics works the same way. Schedules are filled, handovers happen, and dashboards show movement. However, movement alone does not indicate whether each shift is truly connected to the next or merely a means of getting through the hours.

Measuring engagement in shift-based logistics operations is how leaders sense that difference early. It helps reveal whether teams are aligned across shifts, alert during long hours, and steady under pressure, or whether the operation is quietly running on fumes.

- Engagement in shift-based logistics erodes at handovers, so it must be measured continuously at the shift level, not averaged quarterly.

- Traditional surveys miss frontline realities; short, mobile-friendly pulses capture engagement without disrupting work.

- Strong measurement blends sentiment with operational signals like coverage gaps, adherence, and voluntary shift pickup.

- Data only matters when leaders act quickly, close feedback loops, and show visible progress across all shifts.

- Fair, consistent engagement measurement strengthens stability, safety, and performance in round-the-clock logistics operations.

Why traditional engagement surveys fail in shift-based logistics environments

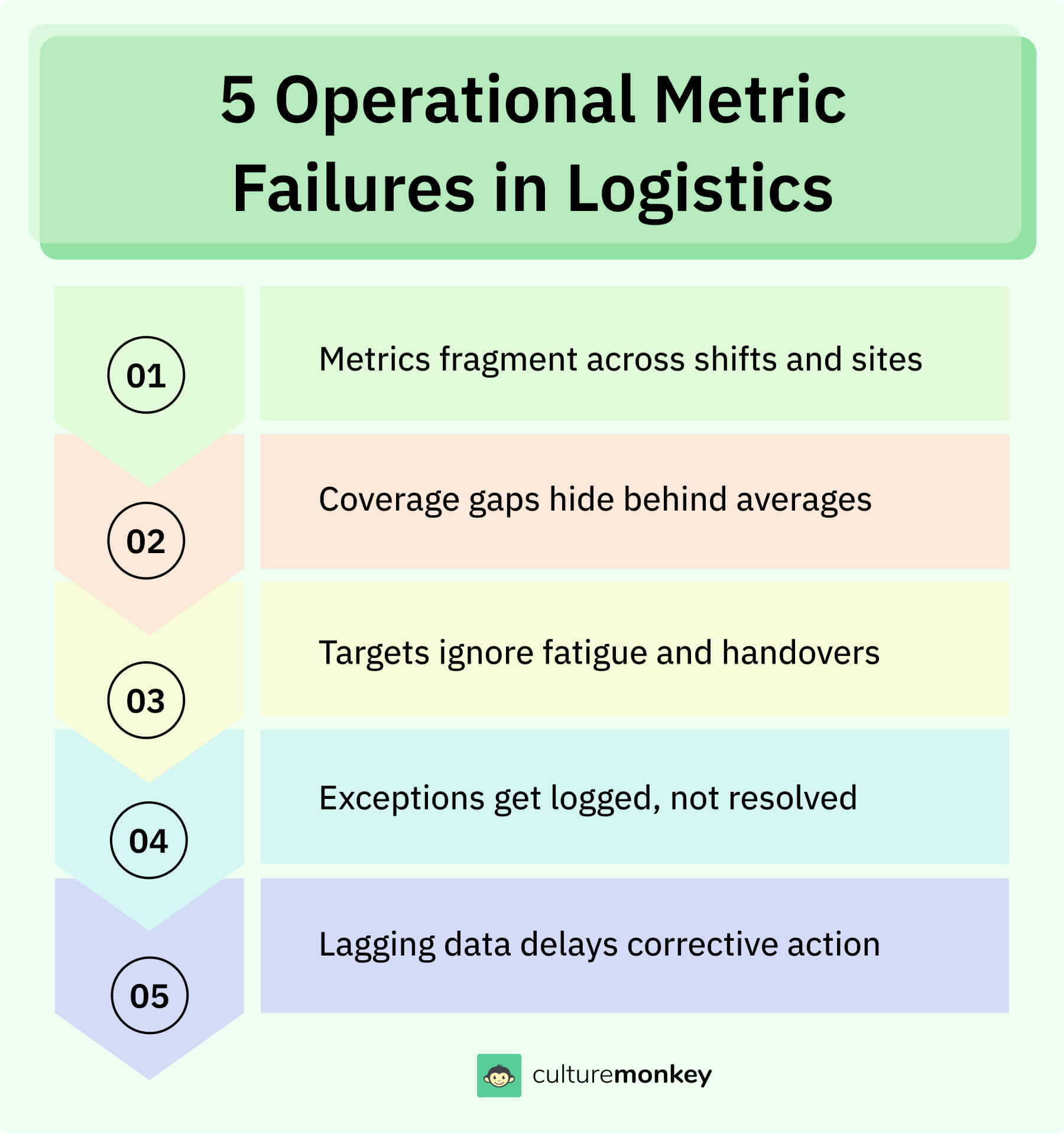

Traditional surveys in multi-shift logistics environments are like trying to steer a 24/7 logistics operations workforce using yesterday’s weather report. By the time results land, day and night shift logistics teams have already rotated. The questions miss Warehouse shift work challenges, so leaders get tidy averages instead of what’s actually happening inside logistics operations.

- Timing mismatch: Rotating shifts in logistics operations mean many logistics employees never see the survey link, so employee engagement in logistics looks healthier than it is.

- One-size questions: Warehouse and delivery staff face different moments than office teams, so the logistics industry gets generic answers with low signal for operational efficiency.

- Channel friction: Without employee engagement tools built for floor access, frontline employees skip long forms, and engaged employees become silent.

- No action loop: When employee engagement software reports arrive late, engaged employees feel valued less, and trust drops across the logistics sector.

- Manager blind spots: Multi-shift logistics environments hide patterns, so engaged workforce pockets get missed while issues spread.

- Support gaps: Surveys rarely surface mental health resource needs in time, so fatigue builds and engagement KPIs for shift-based logistics teams drift.

- Recognition misses: Without recognition programs tied to shift realities, engaged employees stop seeing what good looks like.

- Weak segmentation: Traditional dashboards cannot separate day and night shift logistics teams, so leaders cannot connect engagement KPIs for shift-based logistics teams to operational efficiency.

So instead of chasing big, slow survey scores, shift leaders need fast, practical signals that reflect how logistics employees show up across handovers, peaks, and long hours. Next, we’ll break down key engagement signals to track in shift-based logistics teams.

Key engagement signals to track in shift-based logistics teams

Measuring engagement across logistics shifts is like running a control tower with fog outside. You cannot rely on one big view. You watch the small lights that warn you early. For logistics leaders, these signals show engagement challenges in shift-based logistics before they hit customer satisfaction or break company culture.

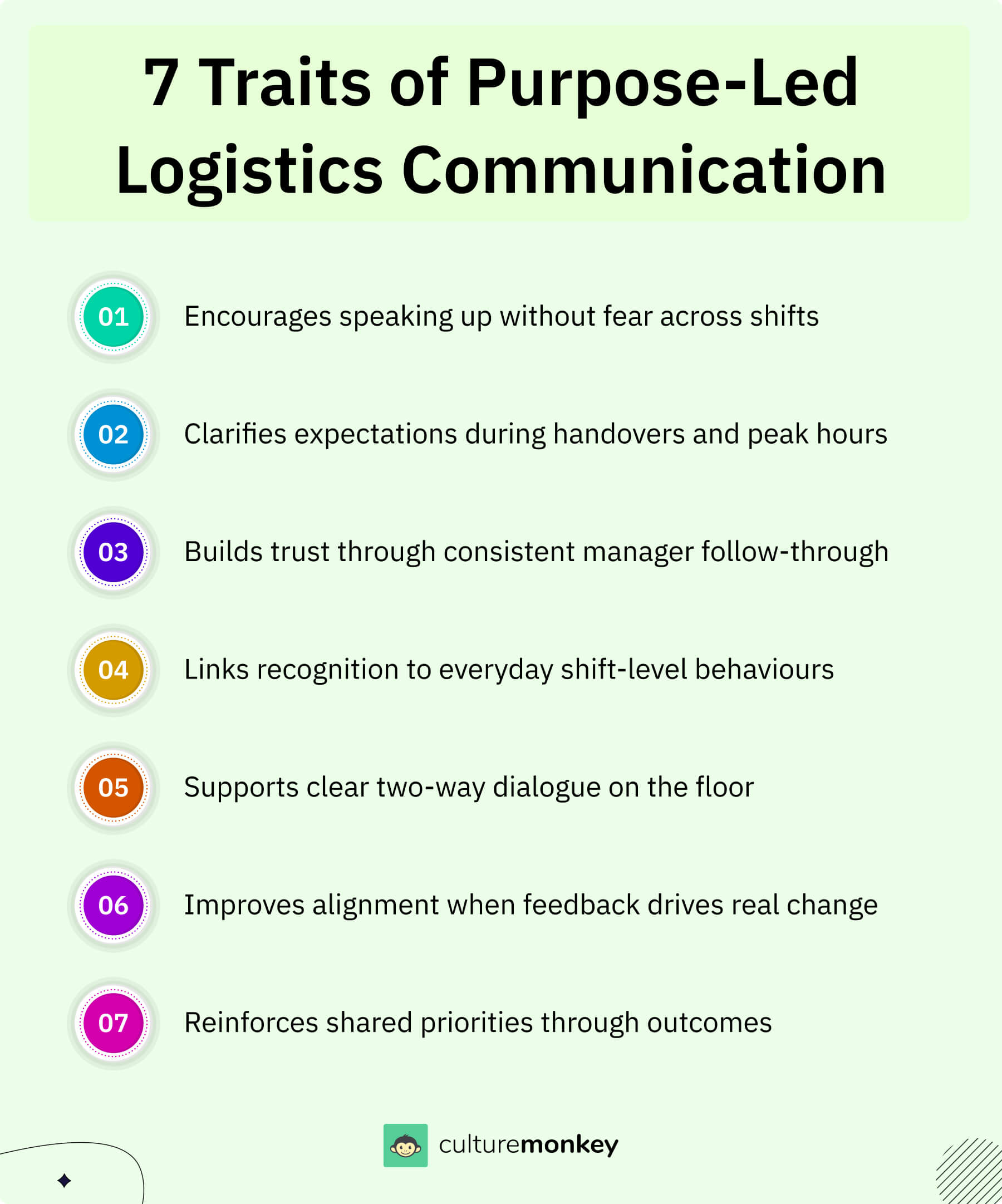

- Handover clarity: Track if frontline workers report smooth handoffs across employee engagement in logistics shifts, because handover gaps quickly become misses in key performance metrics for warehouse teams.

- Micro-feedback cadence: Use employee engagement platforms for real-time engagement tracking in logistics, so logistics organisations catch issues early and turn them into actionable insights.

- Absence pattern shifts: Watch unexpected call-outs by shift, since employee well-being dips first and shift-based workforce engagement drops next.

- Safety near-miss notes: Rising near-miss chatter often signals fatigue, so logistics workforce engagement metrics should pair with employee well-being checks.

- Recognition frequency: If thanks is rare, frontline engagement in logistics operations weakens, so engagement strategies should include simple, shift-ready loops that fit warehouse teams.

- Supervisor trust pulse: Measure trust in shift leads, because logistics leaders get faster movement when employee engagement strategies are clear and fair.

- Tool friction flags: Track where scanners, WMS steps, or SOP changes cause drag, since logistics organisations lose momentum when engagement strategies ignore real workflow pain.

- Training follow-through: Check if skill refreshers happen on every shift, because engaged teams stay steadier and employee well-being improves when learning is not “day-shift only.”

- Sentiment by shift type: Segment by weekends, peaks, and night rotation, so logistics organisations can spot uneven company culture and tune engagement strategies by context.

- Predictive risk scoring: Use workforce analytics for shift-based operations and predictive analytics to flag burnout pockets, then convert signals into actionable insights.

- Customer-facing ripple: Link late-stage rework and delivery misses to frontline engagement in logistics operations, because customer satisfaction often slips after engagement strategies drift.

These signals help logistics leaders see shift-based workforce engagement in motion, not just in averages. But signals alone do not change outcomes.

Next, we’ll turn these patterns into a practical, repeatable plan: 12 steps to measuring engagement in shift-based logistics operations.

12 Steps to measuring engagement in shift-based logistics operations

Measuring engagement in shift-based logistics operations is like tuning a relay race, not timing one runner. Each handoff matters more than speed alone. When logistics teams work across rotating shifts, leaders need a repeatable system that captures employee sentiment, closes communication gaps, and reflects real frontline conditions.

1. Define engagement clearly for each shift

- Start by defining what shift-based workforce engagement actually means for each roster.

- For night shifts, it may mean alertness and support.

- For peak shifts, it may mean clarity and pacing.

- Clear definitions anchor logistics, employee engagement metrics, and prevent warehouse staff from being judged by mismatched expectations.

2. Segment teams by shift and role

- Do not group all logistics teams.

- Segment by shift, role, and location to surface warehouse shift engagement challenges.

- Warehouse workers loading trailers face different pressures than pickers or sorters.

- Engagement measurement for warehouse teams only works when comparisons are fair and context-aware.

3. Choose shift-friendly engagement measurement methods

- Shift-based employee feedback must fit the floor.

- Long surveys fail shift workers.

- Use an employee listening platform or engagement platform that supports kiosks, SMS, or mobile prompts.

- This keeps frontline engagement in logistics operations visible without interrupting flow or forcing workers off-task.

4. Set an appropriate measurement cadence

- Quarterly surveys move too slowly for logistics operations.

- Align cadence to operational cycles instead.

- Weekly or bi-weekly pulses help track employee sentiment as conditions change.

- An engagement platform should blend logistics workforce engagement analytics with performance data to detect early drift.

5. Design questions suited for frontline work

- Frontline questions should reflect real moments.

- Ask about handovers, equipment readiness, and workload balance.

- Avoid abstract language.

- When warehouse workers can answer quickly, sentiment analysis becomes sharper and more reliable.

- Clear questions help track employee sentiment without overthinking.

6. Ensure anonymity across small shift teams

- Small shift teams amplify fear of being identified.

- Without anonymity, feedback becomes filtered.

- Protect shift workers by aggregating responses and masking patterns.

- This builds trust with warehouse staff and improves workforce engagement accuracy across logistics teams, where word travels fast.

7. Communicate purpose and align managers early

- Before gathering feedback, explain why it matters and what will change.

- Logistics teams disengage when surveys feel performative.

- Pair the engagement platform with peer recognition programs so managers reinforce progress.

- Clear intent helps boost engagement instead of triggering scepticism.

8. Track participation by shift consistently

- Overall response rates hide gaps.

- Track participation by shift, role, and site to spot access issues or trust drops.

- Low response often signals friction, not apathy.

- Fix channels quickly so workforce engagement signals remain representative across all logistics teams.

9. Analyse trends across shifts and locations

- Measuring engagement across logistics shifts means studying patterns, not chasing one score.

- Compare shifts, sites, and seasons.

- Use logistics workforce engagement analytics and sentiment analysis together to understand cause and effect.

- Prioritise fixes where impact is highest.

10. Share results clearly with all shifts

- Do not limit updates to email or meetings day shift attend.

- Share results in break rooms, shift huddles, and digital boards.

- Connect employee sentiment themes to performance data so warehouse staff see relevance and progress, not just charts.

11. Turn insights into visible actions

- Feedback without action erodes trust.

- Choose a few fixes per site and execute fast.

- Close the loop visibly so frontline engagement in logistics operations feels real.

- When warehouse workers see changes, participation improves, and engagement measurement gains credibility.

12. Repeat measurement and show progress

- Engagement measurement is a cycle, not a one-time effort.

- Recheck the same signals after changes.

- Publish what improved and what did not.

- Consistency builds trust and stabilises shift-based workforce engagement across time, teams, and operational pressure.

Access shift-level engagement insights before gaps impact operations.

Download nowEngagement KPIs for shift-based logistics teams

Engagement KPIs are like a shift control panel: you do not stare at one dial and hope. You watch a few lights that warn you early, across shift management and handovers. With real-time engagement tracking in logistics, logistics managers' engagement responsibilities become clearer because signals directly tie to performance metrics and daily engagement efforts.

1. Digital & platform engagement

Login frequency and app usage

Consistent logins show whether shift teams rely on digital systems as part of daily shift management. Sudden drops often indicate access issues, tool fatigue, or misalignment between how platforms are designed and how logistics teams actually operate on the floor.

Shift marketplace participation

Participation in shift swaps or pickups reflects trust in scheduling fairness and system transparency. Low usage often signals friction, unclear rules, or past negative experiences, making it an early indicator of disengagement in distributed logistics teams.

Communication responsiveness

Response time to shift updates, alerts, or change requests shows how connected teams are in real time. Slow or uneven replies often reveal broken handovers, unclear ownership, or overload during peak operational windows.

Availability update consistency

Regular availability updates indicate planning confidence and predictability. When this slips, shift management becomes reactive, increasing last-minute gaps and stress across teams, especially in multi-location or remote logistics environments.

2. Operational performance metrics

Schedule adherence

On-time starts and planned finishes show whether shifts are realistic and sustainable. Repeated misses usually point to fatigue, overload, or poor planning rather than motivation, making this a critical engagement-adjacent performance signal.

Shift coverage levels

Open shifts and emergency backfills highlight trust and willingness to step in. Healthy coverage suggests fairness and stability, while recurring gaps often signal burnout or disengagement building quietly across specific shifts.

Voluntary shift pickup rates

Willingness to take extra shifts reflects confidence in workload balance and rewards. Declines here often precede higher absenteeism, making this a strong early indicator for reducing disengagement in shift-based operations.

Turnover and absenteeism by shift

Tracking churn and absence by shift reveals where pressure concentrates. Patterns matter more than totals, especially when linked to specific schedules, locations, or operational peaks.

3. Employee experience & feedback

Pulse survey insights

Short, frequent pulses capture real-time sentiment without slowing work. When combined with operational data, they help distinguish between temporary stress and deeper engagement problems across logistics teams.

Shift-specific feedback

End-of-shift feedback captures details while they are fresh. This helps surface practical issues like handovers, equipment readiness, or workload spikes that broader surveys often miss.

Perceived fairness in shift distribution

Fairness strongly influences trust and willingness to engage. When teams feel shifts are balanced and rules are consistent, cooperation rises. When fairness slips, disengagement spreads faster than performance metrics can show.

Common mistakes when measuring engagement in shift-based logistics operations

Measuring engagement here is like calibrating scanners during peak periods while conveyors keep moving. If your settings are off, every label looks “fine” until the pile-up hits. In dispersed teams, small measurement mistakes hide real employee engagement challenges in the logistics industry and delay fixes that protect well-being and workforce stability.

- Treating surveys as strategy: A workforce engagement strategy for logistics companies fails when you collect employee input but never tie it to strategic objectives. This creates stale engagement data, weak consistent communication, and falling employee satisfaction across logistics workers.

- Ignoring shift and site context: Aggregating dispersed teams hides engagement trends, especially during peak periods. Without segmentation, frontline managers cannot connect engagement data to safety protocols, scheduling tools, and real shift constraints.

- Measuring too late: Quarterly checks miss fast swings in morale and fatigue. In the employee engagement challenges in the logistics industry, late signals reduce workforce stability because you act after churn, not before.

- Over-indexing on one metric: Relying only on employee satisfaction scores hides root causes. You need engagement trends plus operational signals, or strategic objectives get met briefly while well-being declines underneath.

- Skipping frontline manager enablement: Frontline managers are asked to “drive engagement” without tools or time. This breaks consistent communication and weakens employee input quality, making engagement data noisy and hard to act on.

Source: (Gallup)

- Using channels that do not fit shifts: If feedback needs desktops, it will miss the floor. Use mobile devices and shift-ready workflows, or dispersed teams will opt out, and you will misread engagement trends.

- Confusing compliance with engagement: Strong safety protocols are non-negotiable, but compliance scores are not engagement. Treating them as the same masks, burnout and employee experience strategy for logistics companies becomes reactive.

- No visible action loop: When leaders do not close the loop, employee input drops, and trust erodes. That hurts workforce stability and makes enterprise employee engagement tools for logistics look like “just another system.”

- Wellness without operations fit: Wellness programs that ignore rosters feel performative. Wellness programs work when tied to peak periods, fatigue, and shift recovery, improving well-being in ways logistics workers can actually use.

- Black-box analytics without trust: Machine learning algorithms can spot risk, but if leaders cannot explain why, action stalls. Keep insights simple, align them to strategic objectives, and show how engagement data becomes decisions.

Avoiding these mistakes is half the battle. The other half is having a system built for shift realities: mobile-first access, smart segmentation, and fast action loops. Next, we’ll cover how CultureMonkey supports engagement measurement in shift-based logistics operations.

How CultureMonkey supports engagement measurement in shift-based logistics operations?

CultureMonkey works like a control system for shift feedback. It captures what crews experience during handovers, peaks, and long hours, then surfaces patterns leaders can act on before problems compound.

For leaders measuring engagement in shift-based logistics operations, the focus is speed, clarity, and consistent follow-through across rosters and sites.

- Shift-ready pulse surveys: Collect short, mobile-friendly pulses designed for breaks and handovers, so teams can share feedback without slowing work or disrupting operations.

- Location-level segmentation: View insights by site and role to surface uneven engagement early. This helps improve manager effectiveness in warehouse operations by making issues visible where they actually occur.

- AI-assisted theme analysis: Automatically surface recurring themes from open-text responses, helping teams move from raw feedback to priorities faster. This supports building a feedback culture in logistics organisations without manual analysis overhead.

- Manager dashboards with guided follow-up: Provide frontline leaders with clear summaries and prompts, helping them respond consistently across rotating rosters and avoid feedback stalling after collection.

- Engagement trend monitoring over time: Track changes across weeks and months instead of relying on one-off scores. Seeing early dips in trust, fatigue, or fairness enables earlier intervention, reducing frontline attrition in logistics workforce by detecting risk before exits surface.

- KPI alignment without overloading teams: Link engagement trends to engagement KPIs for logistics and supply chain teams, helping leaders understand which logistics workforce motivation techniques are working and where adjustments are needed.

Conclusion

Measuring engagement in shift-based logistics operations is no longer a nice-to-have. In environments where work moves around the clock, small gaps between shifts quietly compound into safety risks, service delays, and attrition. Engagement becomes the early warning system. It shows whether handovers are holding, whether pressure is building, and whether teams still feel supported when leaders are not physically present.

For logistics leaders, this visibility matters because traditional signals arrive too late. By the time turnover rises or coverage drops, trust has already eroded. Measuring engagement consistently helps organizations spot friction early, respond faster, and stabilise performance across shifts.

CultureMonkey supports this by making engagement measurement practical for shift-based realities. With short pulse surveys, shift-level segmentation, and clear action tracking, teams move beyond collecting feedback to actually acting on it. The result is not just better data, but stronger manager follow-through, lower frontline attrition, and logistics operations that stay resilient under constant pressure.

Book a demo with CultureMonkey.

FAQs

1. How do you measure engagement in shift-based logistics operations without disrupting work?

Measure employee engagement in logistics using mobile apps designed for breaks and handovers. Leading logistics providers use employee engagement tools and employee engagement software to gather employee feedback quickly. This reduces communication gaps in supply chain teams, addresses employee engagement challenges in logistics industry, supports sentiment tracking, and protects productivity benchmarks while keeping frontline employees focused on work.

2. What engagement metrics are most effective for shift-based logistics teams?

The most effective metrics combine sentiment tracking with behaviour signals like participation, response speed, and recognition program usage. Employee engagement in logistics improves when logistics companies connect these key metrics to employee efforts and productivity benchmarks. This approach helps reduce frontline attrition while improving morale among warehouse workers across shifts.

3. How can logistics companies fairly compare engagement across different shifts?

Logistics companies should segment employee engagement in logistics by shift, role, and location instead of relying on averages. Fair comparisons use normalised key metrics, not raw scores. Supported by employee engagement tools, this method helps leadership employees identify communication gaps in supply chain teams while building a feedback culture without penalising specific shifts.

4. Why do night and rotating shifts often show lower engagement scores?

Employee engagement in logistics often drops on night and rotating shifts due to limited leadership visibility, weaker recognition programs, and delayed communication. These conditions intensify employee engagement challenges in logistics industry. Without focused employee engagement strategies, logistics companies struggle with improving morale among warehouse workers and maintaining an engaged workforce across non-standard shifts.

5. How often should engagement be measured in shift-based logistics operations?

Leading logistics providers avoid annual surveys and rely on frequent pulses aligned with operations. Employee engagement in logistics improves through continuous feedback loops enabled by mobile apps, employee engagement software, and employee engagement tools. This cadence helps logistics companies spot issues early, reduce frontline attrition in logistics workforce, and sustain engaged employees across shifts.

6. What should leaders do after collecting engagement data from shift-based teams?

Leadership employees must act quickly and visibly after collecting employee feedback. Sharing results, addressing communication gaps, and reinforcing recognition programs help employees recognise progress. Employee engagement in logistics strengthens when companies focus on building a feedback culture in logistics organizations, improving morale among warehouse workers, and turning insights into actions that frontline employees can experience.